Optimizing CNC Machine Performance for Manufacturers

Table of Contents

- Supercharge Your CNC: A Product-Focused Guide for Small & Custom Manufacturers

- 1. Start With Tooling: Premium Cutters That Do More, Faster

- 2. Feed Rate & Toolpath Optimization: Don’t Leave Speed on the Table

- 3. Faster Setup: Accessories That Save Minutes on Every Job

- 4. Preventive Maintenance: Protect Accuracy & Uptime

- 5. Smart Machine & Accessory Upgrades (Without Replacing Everything)

- 6. Operator Skill: Your Most Valuable Productivity Tool

- Conclusion: Small Shops Win With the Right Tools + Strategy

- FAQs

Supercharge Your CNC: A Product-Focused Guide for Small & Custom Manufacturers

Small and custom manufacturers thrive on versatility, precision, and speed. The right CNC optimization strategy — combined with the right tooling — can dramatically cut cycle times, reduce rework, and increase profitability.

This guide walks through practical performance strategies for smaller shops and highlights specific products that make them real.

Spiral-flute bits combine a shearing action in cutting with an augering action in chip clearance. The shearing action yields an especially clean accurate cut while the augering action clears chips from the cut. The ‘Down-Cut’ cuts from the surface down leaving a smooth edge at the surface.

Spiral-flute bits combine a shearing action in cutting with an augering action in chip clearance. The shearing action yields an especially clean accurate cut while the augering action clears chips from the cut. The ‘Down-Cut’ cuts from the surface down leaving a smooth edge at the surface.1. Start With Tooling: Premium Cutters That Do More, Faster

The fastest way to improve CNC performance — without replacing equipment — is by selecting the right cutting tools. Tool geometry, coating, flute design, and material compatibility all influence how aggressively you can run feeds and speeds, how clean the finish is, and how long the tool lasts before replacement.

Key categories of high-performance cutters to consider:

- Solid Carbide Spiral End Mills

Ideal for high-speed cutting and precision profiling in wood, plastics, and non-ferrous metals. Available in up-cut, down-cut, and compression geometries depending on chip evacuation needs and surface finish goals. - Compression & Up/Down Cut Bits for Sheet Goods

Compression spirals are designed to minimize tear-out on plywood, laminates, and veneered material — perfect for cabinet, furniture, and signmaking applications. - Ball Nose & Tapered Ball Nose Cutters

Used for 3D contouring, relief carving, molds, and detailed surface finishes. A go-to tool for sign shops and small custom manufacturers producing organic shapes and detailed artistic work. - Specialty Coated End Mills for Metals & Composites

Coatings such as AlTiN, TiB2, or diamond-like coatings help dissipate heat, reduce tool wear, and maintain edge life when cutting abrasive materials like aluminum composites, carbon fiber, and stainless steel. - Starter & Application-Focused Bit Sets

Bundled sets help standardize tooling, reduce trial-and-error, and ensure consistent quality. Ideal for new CNC users or shops expanding into more material types.

When choosing tooling, consider your most common materials, desired surface finish, required tolerance, and production volume. Higher-quality bits typically allow faster feed rates and longer tool life — paying for themselves over time.

2. Feed Rate & Toolpath Optimization: Don’t Leave Speed on the Table

Many small shops run their CNC machines more slowly than they need to — either out of caution or because their toolpaths were never tuned beyond “safe defaults.” That’s hidden capacity you can reclaim.

Practical steps:

- Use tooling manufacturer chip-load charts as a baseline, then test and document optimal feeds and speeds by material.

- Leverage adaptive or high-speed toolpaths in your CAM software to keep cutter engagement consistent.

- Use multi-purpose drill/mill tools where possible to reduce the number of tool changes in a program.

- Pair high-performance solid carbide tools (like the AlTiN-coated spirals above) with aggressive but safe toolpaths.

Even a modest 10–20% increase in feed rates on your core jobs can translate into hours saved per week, without buying a new machine.

3. Faster Setup: Accessories That Save Minutes on Every Job

Setup time is one of the biggest hidden costs for small and custom manufacturers, especially when you’re running short batches or one-off jobs. Standardizing fixturing and workflows is just as important as the tools in the spindle.

Ways ToolsToday can help:

- CNC Accessories & Workholding

From vacuum table solutions to clamps and hold-downs, the right accessories make it faster to locate and secure parts.

Browse Everything CNC & Accessories - Organized Bit Storage

Keep your most-used tools in labeled, consistent locations so operators can swap cutters quickly and reliably.

Combine these accessories with simple standard operating procedures (SOPs) so every operator sets up the machine the same way every time.

4. Preventive Maintenance: Protect Accuracy & Uptime

A well-maintained CNC machine holds tighter tolerances, runs more smoothly, and breaks fewer tools. Small shops can’t afford surprise downtime, so a basic preventive maintenance routine is a must.

Maintenance focus areas:

- Clean the spindle taper, collets, and holders regularly to maintain secure, accurate tool clamping.

- Inspect rails and ball screws for debris and wear; keep them properly lubricated.

- Monitor spindle runout and vibration, especially when pushing higher speeds and feeds.

- Check and replace worn collets and toolholders — a small investment that can significantly extend tool life.

Pair your maintenance checklist with high-quality tooling and holders, and you’ll get more consistent results on every job.

5. Smart Machine & Accessory Upgrades (Without Replacing Everything)

You don’t always need a brand-new machine to gain performance. Strategic upgrades can unlock major improvements in capacity and flexibility.

Upgrade ideas from ToolsToday:

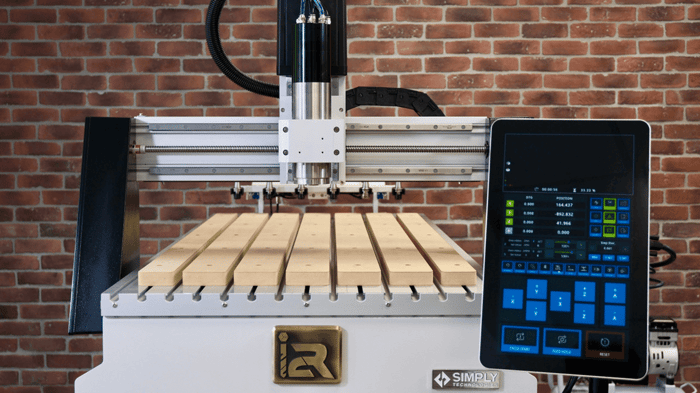

- CNC Machines for Small Shops

From compact machines for tight spaces to production-ready routers, ToolsToday offers options sized for small and mid-sized manufacturers.

Explore CNC Machines - Vacuum Systems & Dust Collection

Vacuum tables and dust management systems improve workholding, surface quality, and the safety of your work environment. - CNC Software & Training

Pair your tools and machines with the right software and training resources to help operators program faster and cut smarter.

6. Operator Skill: Your Most Valuable Productivity Tool

Even the best hardware and tooling depend on informed decisions at the machine. For small and custom manufacturers, one skilled operator can elevate the performance of the entire shop.

Training topics that pay off:

- CAM strategy: roughing vs. finishing, climb vs. conventional cutting, and toolpath optimization.

- Material-specific feeds, speeds, and entry strategies (especially for metals and composites).

- Tool selection for different materials, cut depths, and required surface finishes.

- Basic troubleshooting for chatter, poor finish, and tool breakage.

Encourage operators to document successful settings and tooling combinations, then standardize them as “recipes” for future jobs.

Conclusion: Small Shops Win With the Right Tools + Strategy

Optimizing CNC performance doesn’t always require a huge capital investment. By combining smart tooling choices, efficient toolpaths, organized setups, and consistent maintenance, small and custom manufacturers can:

- Produce more jobs per shift

- Improve consistency and surface finish

- Reduce scrap and rework

- Increase profit per part and per project

ToolsToday’s broad catalog of CNC tooling, machines, and accessories gives you everything you need in one place to push your existing equipment further.

Start here:

Shop Everything CNC at ToolsToday

FAQs

How can a small shop improve CNC machine performance without buying a new machine?

Start by upgrading tooling, dialing in feeds and speeds, and standardizing setups. High-quality cutters, better workholding, and basic preventive maintenance often unlock more speed and accuracy from the CNC you already own.

What types of CNC cutters are best for small and custom manufacturers?

Versatile solid carbide spiral bits, compression bits for sheet goods, and a small set of dedicated end mills for metals and composites cover most jobs. A curated CNC router bit set from ToolsToday can give small shops a reliable “base kit” for daily work.

How do I choose the right feeds and speeds for my CNC tooling?

Start with the chip-load and RPM recommendations from the tooling manufacturer, then adjust based on your material, spindle power, and tool diameter. Make test cuts, document successful settings, and reuse those “recipes” for future jobs.

Which ToolsToday products should I prioritize to optimize my CNC workflow?

Focus first on industrial-quality CNC router bits or end mills, then add accessories that cut setup time, such as better workholding, vacuum solutions, and organized bit storage. These upgrades typically deliver faster payback than a full machine replacement.

How often should I replace CNC router bits and end mills?

Replace tools when you see burning, poor surface finish, increased spindle load, or the need to slow feeds and speeds to avoid chatter. For production or critical work, many shops retire cutters on a schedule to maintain consistent quality and avoid mid-job failures.