Best CNC Router Bits for Cutting Aluminum

Table of Contents

- Top ZrN-Coated Options for Clean Cuts, Better Finishes & Longer Tool Life

-

- 1. Solid Carbide Spiral O-Flute ZrN-Coated Up-Cut Router Bits

-

- 2. Zero-Point Solid Carbide V-Groove Router Bits with ZrN Coating (45°, 60°, 90°)

- 2D/3D Carving Bits with ZrN Coating also available in sets, from 3 to 18 pieces

- 3. CNC Ball Nose (Conical Ball) Solid Carbide Spiral ZrN-Coated Router Bits

-

- Why ZrN-Coated Router Bits Are Ideal for Aluminum

- Choosing the Right CNC Bit for Aluminum

- Feeds & Speeds Tips for Cutting Aluminum on a CNC Router

- Final Thoughts

- FAQs

Top ZrN-Coated Options for Clean Cuts, Better Finishes & Longer Tool Life

Aluminum is one of the most rewarding—and unforgiving—materials to cut on a CNC router. When your tooling is right, aluminum machines cleanly, leaves crisp edges, and produces professional results. When it’s wrong, you’ll see chatter, poor finishes, chip welding, and premature tool failure.

At ToolsToday, three ZrN-coated solid carbide CNC bit styles consistently rise to the top for aluminum work. Each serves a different purpose, from high-feed production cutting to precision beveling and detailed 3D machining.

Below, we break down when to use each bit type, what makes it effective for aluminum, and how to choose the right one for your job.

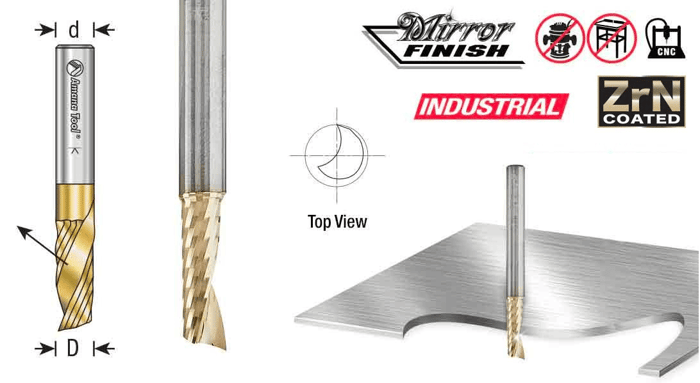

1. Solid Carbide Spiral O-Flute ZrN-Coated Up-Cut Router Bits

Best for: Fast, clean aluminum cutting with high feed rates

If you’re cutting aluminum on a CNC router with automatic feeding, O-flute spiral bits should be your starting point.

These bits are engineered specifically for soft, gummy metals like aluminum, using a single, highly polished flute to evacuate chips efficiently before they can re-weld to the cutting edge.

Why O-Flute Bits Excel in Aluminum

- Mirror-polished cutting edge reduces friction and heat buildup

- Large flute volume clears chips quickly, even at higher feed rates

- ZrN coating resists galling and extends tool life

- Enables higher feed rates for more linear feet cut in less time

This combination makes O-flute bits ideal for production environments, especially when cutting aluminum sheets, panels, and profiles used in windows, doors, and architectural facades.

Use these when:

- You want maximum speed and clean edges

- Your CNC has good rigidity and automatic feed control

- Surface finish matters, but throughput matters more

Shop Solid Carbide CNC Spiral O-Flute Aluminum Cutting ZrN Coated Up-Cut Router Bits

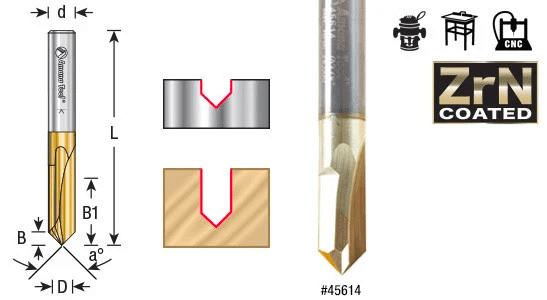

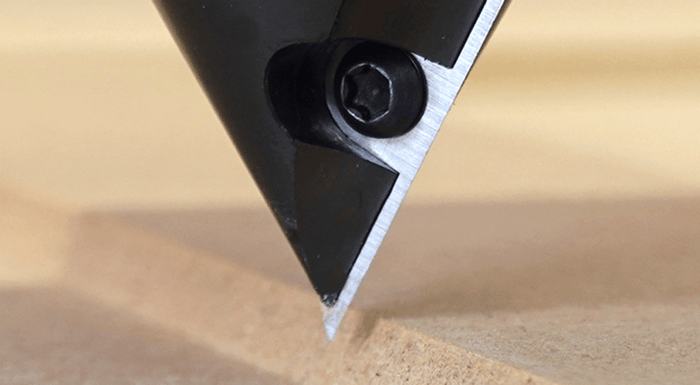

2. Zero-Point Solid Carbide V-Groove Router Bits with ZrN Coating (45°, 60°, 90°)

Best for: V-grooving, beveling, engraving, and chamfering aluminum

V-groove router bits aren’t just for wood or plastic. When properly coated and ground, they are extremely effective for precision aluminum detailing.

Zero-Point V-Groove bits feature solid carbide construction with ZrN coating, allowing them to create crisp bevels, chamfers, and engraved lines without smearing or tearing the material.

Why V-Groove Bits Work in Aluminum

- Sharp, controlled point geometry for clean edge definition

- ZrN ceramic coating reduces friction and helps prevent material buildup

- Ideal for controlled depth cuts and decorative features

Available in 45°, 60°, and 90° angles, these bits are commonly used for:

- V-grooving aluminum panels

- Beveling edges prior to assembly

- Decorative or functional engraving

- Clean chamfers on machined parts

Use these when:

- Edge detail and precision matter more than speed

- You’re engraving, beveling, or chamfering aluminum

- You want consistent geometry with repeatable results

Shop Zero-Point 45°, 60° & 90° Solid Carbide Engraving Router Bits for V-Grooving with ZrN Coating

3. CNC Ball Nose (Conical Ball) Solid Carbide Spiral ZrN-Coated Router Bits

Best for: 2D & 3D contouring, profiling, and deep aluminum machining

For complex shapes, curved surfaces, and detailed profiles in aluminum, ball nose router bits are the tool of choice.

These ZrN-coated solid carbide bits are designed for simultaneous 3-axis motion, making them ideal for 2D and 3D contouring, modeling, and deep profiling.

Why Ball Nose Bits Are Effective

- Up-cut spiral design supports chip evacuation

- Reduced stepping for smoother surface finishes

- ZrN coating helps minimize heat and extend tool life

- Tapered options allow deep cuts with high detail

While widely used in sign making, cabinetry, and mold work, these bits also perform exceptionally well in aluminum when precision and surface quality are critical.

Use these when:

- Machining complex curves or contoured aluminum parts

- Performing deep profiling with fewer passes

- Creating 2D or 3D features where finish quality is critical

Shop CNC Ball Nose (Conical Ball) Solid Carbide Spiral 2D/3D Carving ZrN Coated Up-Cut Router Bits

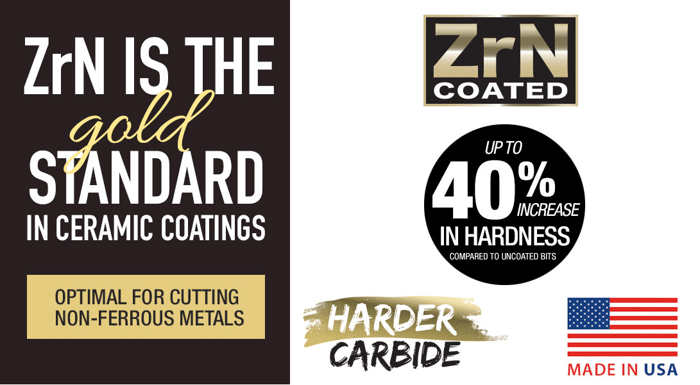

Why ZrN-Coated Router Bits Are Ideal for Aluminum

All three bit types above share a key advantage: Zirconium Nitride (ZrN) coating, applied using a PVD (Physical Vapor Deposition) process.

Key Benefits of ZrN Coating

- Creates a hard, wear-resistant ceramic surface over carbide

- Reduces friction and helps prevent chip welding and galling

- Supports higher feed rates and spindle speeds

- Extends cutting edge life significantly

- Produces cleaner finishes with less chatter

Combined with optimized flute geometry and low Total Indicated Runout (TIR), ZrN-coated tools can reduce secondary cleanup when used on rigid CNC machines and low-TIR spindles.

Choosing the Right CNC Bit for Aluminum

| If your goal is… | Choose this bit |

|---|---|

| Fast production cutting | O-Flute Spiral Up-Cut |

| Engraving, beveling, chamfers | V-Groove (45°, 60°, 90°) |

| Curves, contours, 3D profiling | Ball Nose / Conical Ball |

Feeds & Speeds Tips for Cutting Aluminum on a CNC Router

- Use aluminum-specific bits such as O-flute or ZrN-coated tools for proper chip evacuation

- Prioritize feed rate over spindle speed to avoid heat buildup and chip welding

- Start with conservative depth of cut and increase gradually as your machine allows

- Maintain consistent chip load; rubbing causes poor finishes and short tool life

- Use low Total Indicated Runout (TIR) spindles and secure workholding

- Clear chips aggressively using air blast or vacuum

- Test on scrap before committing to production cuts

Final Thoughts

Cutting aluminum successfully on a CNC router comes down to chip control, heat management, and tool geometry. The ZrN-coated solid carbide bits highlighted above are designed to address all three—delivering cleaner cuts, longer tool life, and more predictable results.

Whether you’re running production parts, engraving panels, or machining complex 3D profiles, choosing the right aluminum-specific CNC bit will save time, reduce scrap, and improve your finished work.

FAQs

What type of CNC router bit is best for cutting aluminum?

O-flute solid carbide router bits are generally the best choice for cutting aluminum on CNC routers because their large flute design clears chips efficiently and reduces heat buildup and chip re-welding.

Why are O-flute bits recommended over multi-flute bits for aluminum?

Aluminum is a soft, gummy metal. O-flute bits use a single, highly polished cutting edge that allows chips to evacuate quickly, preventing material from sticking to the tool and degrading the finish.

Can V-groove router bits be used on aluminum?

Yes. Solid carbide V-groove router bits with ZrN coating are effective for engraving, beveling, chamfering, and V-grooving aluminum when used with proper feeds, speeds, and rigid CNC machines.

When should I use a ball nose router bit for aluminum?

Ball nose router bits are best for 2D and 3D contouring, curved surfaces, profiling, and detailed aluminum machining where smooth transitions and surface finish are important.

What does ZrN coating do for aluminum cutting tools?

Zirconium Nitride (ZrN) coating reduces friction, prevents chip welding, resists wear, and allows for higher feed rates and spindle speeds, resulting in cleaner cuts and longer tool life.

Can ZrN-coated router bits run faster than uncoated bits?

Yes. ZrN-coated bits can typically handle higher spindle speeds and feed rates than uncoated tools because the coating reduces heat and friction at the cutting edge.

Do I need coolant when cutting aluminum on a CNC router?

Coolant is not always required, but proper chip evacuation, correct feeds and speeds, and ZrN-coated tooling can significantly reduce heat and material buildup when cutting aluminum dry.

What causes aluminum to stick to a router bit?

Aluminum can stick to a bit due to excessive heat, poor chip evacuation, incorrect feeds and speeds, or using tools without polished flutes or aluminum-specific coatings like ZrN.

How do I get the cleanest finish when cutting aluminum on a CNC router?

Use aluminum-specific tooling such as O-flute or ZrN-coated router bits, ensure proper chip evacuation, maintain low tool runout, and match feeds and speeds to your machine’s rigidity.

Why is feed rate more important than spindle speed when cutting aluminum?

Feed rate controls chip load. If the feed is too slow, the tool rubs instead of cutting, creating heat that can cause aluminum to weld to the bit and ruin the finish.

What happens if spindle speed is too high when cutting aluminum?

Excessive spindle speed can generate too much heat, leading to chip welding, poor surface finish, and premature tool wear, especially on small-diameter bits.

Should I take shallow or deep passes when cutting aluminum on a CNC router?

It’s best to start with conservative depths of cut and increase gradually. Deeper passes are possible with rigid machines and aluminum-specific tooling, but pushing too far can cause chatter or tool failure.

Why does aluminum sometimes leave a smeared or melted-looking edge?

This usually happens when heat builds up due to incorrect feeds and speeds, poor chip evacuation, or using tools without polished flutes or aluminum-specific coatings.

Do different aluminum alloys require different feeds and speeds?

Yes. Softer alloys like 6061 machine more easily, while harder alloys like 7075 may require reduced speeds, shallower cuts, or more rigid setups.

How does tool diameter affect feeds and speeds?

Smaller diameter tools generally require higher spindle speeds and lighter cuts, while larger tools can handle lower speeds and heavier chip loads, depending on machine rigidity.

Why is machine rigidity important when setting feeds and speeds?

Less rigid machines are more prone to chatter and deflection, which may require slower feeds and shallower cuts. Rigid CNC machines can safely run faster and deeper.