Best Router Bits for Cutting Aluminum Composite Material (ACM) Panels

Aluminum Composite Material (ACM) panels, such as Alucobond® and Dibond®, are widely used in architectural cladding, signage, and interior design due to their lightweight yet durable properties. However, cutting and shaping these materials requires specialized router bits to ensure clean, precise results without damaging the panel.

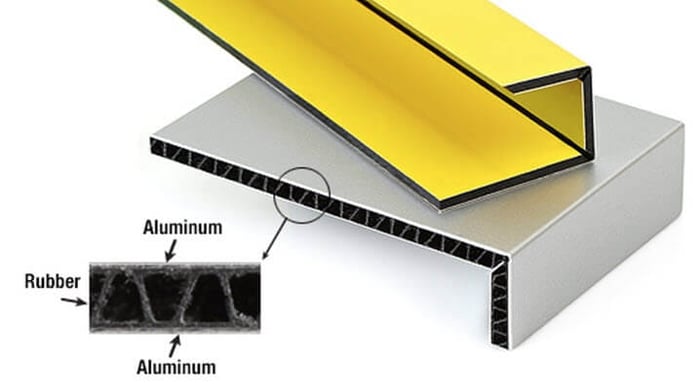

What Are Aluminum Composite Material (ACM) Panels?

ACM panels consist of two thin aluminum sheets bonded to a non-aluminum core, usually made of polyethylene or fire-resistant mineral-filled material. They offer:

- High strength-to-weight ratio

- Weather and UV resistance

- Easy machining and forming

- Various color and texture options

Challenges of Cutting ACM Panels

Using standard woodcutting router bits on ACM panels can lead to:

- Frayed edges and rough cuts

- Poor chip evacuation, causing clogging

- Material delamination

- Excessive tool wear

Choosing the Best Router Bits for ACM Panel Cutting

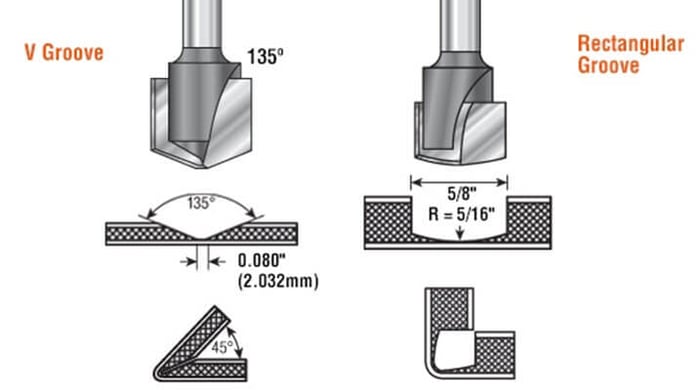

To achieve clean, precise cuts, use router bits specifically designed for ACM, such as:

- Compression Router Bits: Reduces chipping and delamination.

- Single Flute Router Bits: Enhances chip evacuation for high-speed cutting.

- V-Groove Router Bits: Scores panels for easy, accurate folding.

- Upcut Spiral Router Bits: Aids in chip removal and prevents overheating.

- Flat Bottom Router Bits: Provides clean, precise bottom cuts.

Key Features of ACM Router Bits

Look for these essential features when selecting ACM router bits:

- Shear Cut Geometry: Reduces cutting force for smooth edges.

- Helical Cutter Design: Minimizes vibration for cleaner cuts.

- Diameter Tolerance: Ensures precision in CNC applications.

- Chip Evacuation Channels: Prevents material buildup and overheating.

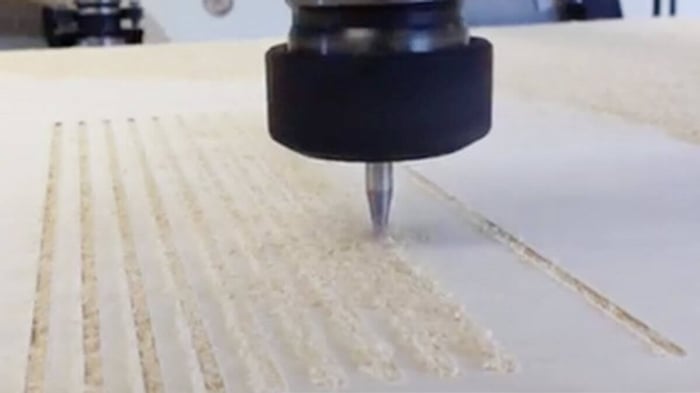

Best Practices for CNC ACM Panel Cutting

To optimize ACM cutting, follow these tips:

- Feed and Speed Optimization: Adjust chip load per tooth for efficiency.

- Material Removal Rate Considerations: Balance speed with cut quality.

- Plunge Cutting Techniques: Start cuts correctly to avoid damage.

- Stack Cutting ACM Panels: Cut multiple panels simultaneously for efficiency.

- Router Collet Compatibility: Ensure a secure fit for stability and precision.

Avoiding Common ACM Cutting Issues

Prevent these common problems when routing ACM:

- Substrate Adhesion Issues: Use the correct cutting technique to prevent delamination.

- Overheating and Melting Core Material: Adjust speeds and maintain sharp tools.

- Excessive Tool Wear: Use high-quality carbide-tipped bits for durability.

Recommended ACM Router Bits from Amana Tool®

Using the right router bits is essential for clean, efficient ACM panel cutting. Whether you're working with Alucobond®, Dibond®, or similar materials, investing in high-quality Amana Tool® ACM bits ensures precision, durability, and superior results.

Explore our selection of ACM router bits today for the best cutting performance!