Foam Cutting: Selecting the Best Bit for Your Project

Choosing the right bit is key to achieving precision and efficiency in foam cutting. Whether you're working on a DIY project or industrial scale production, understanding foam types, bit compatibility, and cutting techniques ensures optimal results.

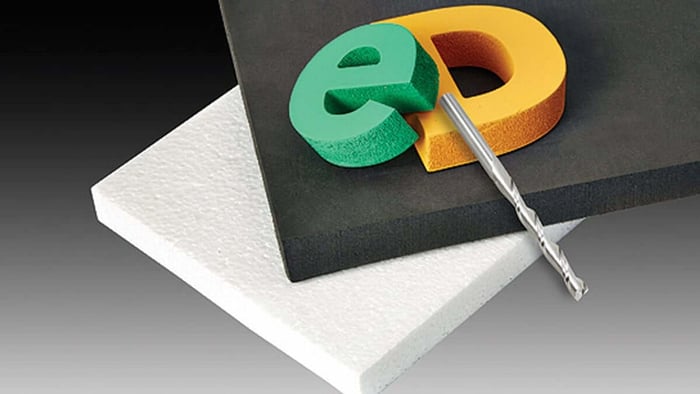

Types of Foam and Their Properties

Foam varies in density and application, influencing the cutting method and tool needed. For example, open-cell foam is used for soundproofing, while closed-cell foam provides thermal insulation. Memory foam and polyurethane foam are more versatile, commonly found in furniture and mattresses. Polystyrene is used in packaging and insulation.

The foam’s density affects cutting techniques. Softer foams can be cut with basic bits, while denser materials require sharper, more specialized bits. A heated wire or sharp knife is often ideal for clean cuts, especially for synthetic foams that can release dust or fumes. Work in a well-ventilated area for safety.

4-Flute Spiral, Up-Cut Router Bits for Deeper Reach Titanium Nitride (TiN) coating increase strength and durability.

4-Flute Spiral, Up-Cut Router Bits for Deeper Reach Titanium Nitride (TiN) coating increase strength and durability.Choosing the Right Bit

Selecting the appropriate bit depends on the foam type, thickness, project size, and the finish required. Here's a breakdown of key factors to consider:

1. Foam Material

Different foam types, such as EVA, polyethylene, and polyurethane, have varying densities. Denser foams require sharper bits to slice through effectively, while softer foams need less aggressive tools.

2. Project Size and Shape

The size and design complexity of your project will influence bit selection. Larger pieces need bits that can handle substantial material removal, while intricate cuts benefit from precise, smaller bits.

3. Desired Cut Quality

Some projects require a clean edge finish, while others may demand intricate detailing or a smooth surface. The cutting method—plunge cutting, edge finishing, or contouring—determines the bit to use. For finer detail, specialized bits like spiral or ball nose bits may be needed.

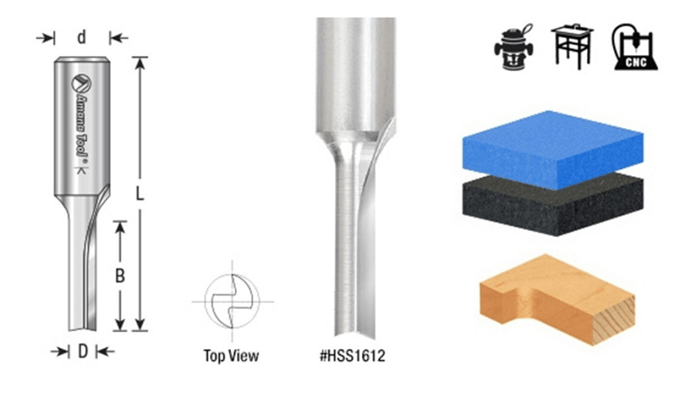

High Speed Steel (HSS) Foam Cutting Straight V Flute Router Bits V flute are selected when a balanced tool is critical for smooth finish. Excellent for hand-fed operations.

High Speed Steel (HSS) Foam Cutting Straight V Flute Router Bits V flute are selected when a balanced tool is critical for smooth finish. Excellent for hand-fed operations.Types of Bits for Foam Cutting

The right bit is essential for clean, accurate foam cuts. Here’s a look at the most common types:

Straight Bits

Straight bits are ideal for straight cuts and clean edges. They work well for basic projects and provide quick cuts, though they can struggle with curves or thick foam.

Spiral Bits

Spiral bits feature a helical design that reduces friction, offering smoother cuts. They’re perfect for detailed, intricate designs and can handle various foam types like memory foam and polystyrene with precision.

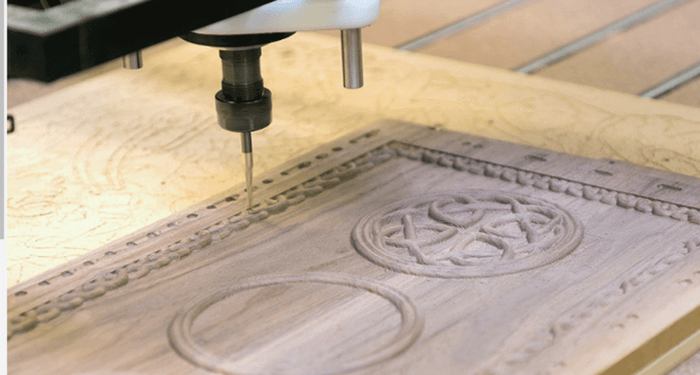

Ball Nose Bits

Ball nose bits are great for carving and detailed work, allowing for smooth, rounded cuts. Ideal for sculpting or three-dimensional foam designs, these bits offer precision and depth.

Tips for Maintaining Your Foam Cutting Bits

To keep your foam cutting bits in top condition, proper maintenance is essential. Regularly sharpen bits, store them properly, and replace them when worn. For sharpening, a fine diamond file works well. Store bits in padded cases to avoid damage, and always follow safety precautions when handling cutting tools.

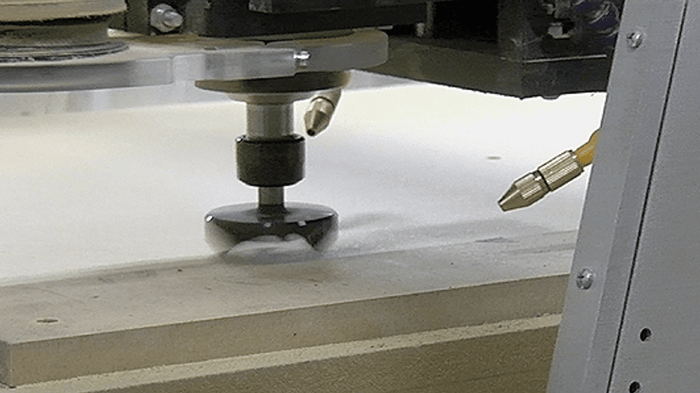

Amana Tool 46566-K SC Spektra Extreme Tool Life Coated Foam Cutting Down-Cut Spiral 1/4 D x 2-1/4 CH x 1/4 SHK x 4 Inch Long Flat Bottom Router Bit.

Amana Tool 46566-K SC Spektra Extreme Tool Life Coated Foam Cutting Down-Cut Spiral 1/4 D x 2-1/4 CH x 1/4 SHK x 4 Inch Long Flat Bottom Router Bit.Frequently Asked Questions

What should I consider when choosing the right bit for my foam project?

Consider the foam material, thickness, desired cut quality, and the complexity of your project when selecting a bit.

What’s the best bit for thicker foam?

A straight bit with a larger diameter is ideal for thicker foam, offering better stability and precision.

Can I use the same bit for all foam types?

No, different foams require different bits. For example, softer foams need less aggressive bits, while denser foams require sharper, specialized bits.

What’s the difference between a straight bit and a spiral bit?

A straight bit is for basic cuts, while a spiral bit provides smoother, more precise cuts and is ideal for detailed work.

How do I choose the right cutting speed?

Start at a slower speed and adjust based on the foam type and bit size. This helps balance cutting speed and precision.

Can foam cutting bits be reused?

Yes, as long as the bits are in good condition. Regularly inspect them for wear and replace or sharpen as needed.