Flute Length, Stickout, and Rigidity: The Underrated Variables in CNC Router Cutting

Table of Contents

- Why Rigidity Matters More on CNC Routers Than Mills

- Flute Length vs Stickout vs Unsupported Length (What Actually Bends)

- Why Small Increases in Length Have Big Consequences

- Why “Minimum Necessary Flute Length” Is a Winning Strategy

- Router-Specific Tradeoffs: Rigidity vs Chip Evacuation

- How Flute Length Interacts with Flute Count

- Practical Rigidity Guidelines for CNC Routers

- Rigidity Checklist (Quick Self-Audit Before You Change Feeds & Speeds)

- The Takeaway

- FAQs

When CNC router cuts go wrong — chatter, poor surface finish, broken tools — the first suspects are usually feeds and speeds, coatings, or even the machine itself.

But one of the most overlooked contributors to cutting performance, especially on CNC routers, is tool rigidity — and more specifically, how much of the tool is unsupported.

In many cases, simply choosing a cutter with a shorter flute length (or reducing stickout) can make a larger difference than changing coatings, flute count, or RPM.

This article explains why flute length and stickout matter so much on CNC routers, and how to think about rigidity when selecting end mills.

Why Rigidity Matters More on CNC Routers Than Mills

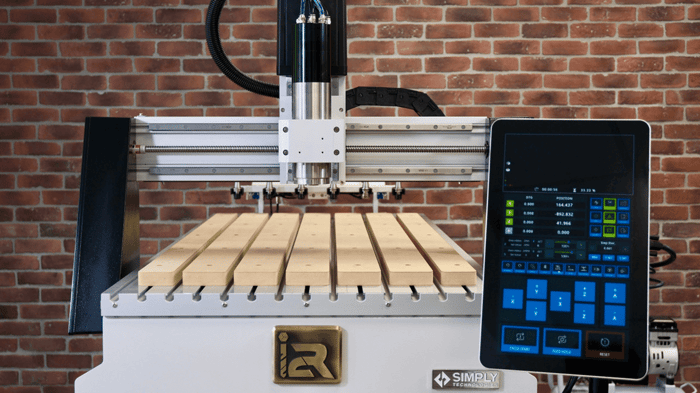

Compared to vertical machining centers, CNC routers typically operate with:

- Higher spindle speeds

- Lower overall mass and stiffness

- Longer tool stickout

- Less inherent damping in the gantry and Z-axis

As a result, routers are far more sensitive to tool deflection and vibration.

When a cutter flexes under load:

- Chip thickness becomes inconsistent

- Cutting forces fluctuate

- Chatter appears

- Surface finish degrades

- Tool life drops

Reducing deflection is often the fastest way to stabilize a cut — and unsupported tool length is one of the biggest contributors to that deflection.

Flute Length vs Stickout vs Unsupported Length (What Actually Bends)

These terms are often used interchangeably, but they aren’t exactly the same.

- Flute length: the cutting portion of the tool

- Stickout: how far the tool extends from the collet

- Unsupported length: the portion of the tool that can flex under cutting load

Unsupported length includes:

- Exposed flute length

- Any exposed shank below the collet

- Any reduced-diameter neck

Stickout is what you measure.

Unsupported length is what bends.

When cutting aluminum on a CNC router,shorter flute lengths are preferred because rigidity and vibration control matter far more than reach.

When cutting aluminum on a CNC router,shorter flute lengths are preferred because rigidity and vibration control matter far more than reach.Why Small Increases in Length Have Big Consequences

From a mechanical standpoint, tool deflection increases with the cube of the unsupported length.

In practical terms:

Doubling the unsupported length of a cutter can reduce stiffness by roughly eight times.

That means:

- A tool with twice the exposed length is not “a little” less rigid — it is dramatically less rigid.

- Small increases in flute length or stickout can have outsized effects on chatter and finish.

This is why two cutters with the same diameter can behave completely differently depending on how much of the tool is unsupported.

Why “Minimum Necessary Flute Length” Is a Winning Strategy

A common mistake — especially among newer router users — is choosing cutters with far more flute length than the cut actually requires.

Examples:

- Cutting 6 mm plate with a 25 mm flute

- Shallow pocketing with long-reach tools

Excess flute length:

- Reduces rigidity

- Encourages vibration

- Makes cutting forces harder to control

A more effective approach is simple:

Choose the shortest flute length that comfortably clears the required depth of cut.

Many users find that this single change:

- Reduces chatter immediately

- Improves edge finish

- Allows higher feed rates at the same depth of cut

Router-Specific Tradeoffs: Rigidity vs Chip Evacuation

Shorter flutes are not a universal fix. On CNC routers, you still need:

- Adequate chip evacuation

- Clearance for adaptive or trochoidal toolpaths

- Enough flute length to avoid rubbing the shank

The goal is not the shortest possible flute — it’s the shortest appropriate flute.

This is why experienced router users often pair:

- Short flute lengths

- Minimal stickout

- Light radial engagement

- Constant-engagement toolpaths

Together, these reduce cutting force spikes while maintaining stability.

How Flute Length Interacts with Flute Count

Flute length also changes how flute count behaves.

On CNC routers:

- Single-flute tools with short flutes often feel extremely stable

- Multi-flute tools benefit disproportionately from reduced flute length

- Longer flutes amplify vibration, especially on 2- and 3-flute cutters

This helps explain why some users report multi-flute cutters “resonating better” in aluminum — not necessarily because of flute count alone, but because rigidity has improved.

Extra-long flute lengths are common on foam-cutting router bits because foam offers very low cutting resistance, allowing deep cuts without the rigidity concerns seen in metals. These tools are designed for reach and clearance, not stiffness.

Extra-long flute lengths are common on foam-cutting router bits because foam offers very low cutting resistance, allowing deep cuts without the rigidity concerns seen in metals. These tools are designed for reach and clearance, not stiffness.Practical Rigidity Guidelines for CNC Routers

While every machine and setup is different, these principles hold up across many router platforms:

- Favor short flute lengths whenever possible

- Minimize tool stickout from the collet

- Use tool diameter to gain rigidity before increasing depth of cut

- Prefer constant-engagement toolpaths over full slotting

- Treat rigidity as a first-order variable, not an afterthought

Once rigidity is addressed, many users find that:

- Feeds and speeds become more forgiving

- Coatings matter less for stability

- Tool life improves naturally

Rigidity Checklist (Quick Self-Audit Before You Change Feeds & Speeds)

Use this quick checklist to troubleshoot chatter, poor finish, or unpredictable tool life — especially on CNC routers.

- ☐ I’m using the shortest flute length that comfortably clears the required depth of cut.

- ☐ Tool stickout is minimized (only as much as needed for clearance and toolpaths).

- ☐ The tool is held in a clean, properly tightened collet (no chips, dust, or residue on the taper/collet).

- ☐ I’m avoiding long-reach / necked tools unless the geometry truly requires it.

- ☐ If rigidity is limiting, I’m considering a larger tool diameter before increasing DOC.

- ☐ I’m using constant-engagement toolpaths (adaptive/trochoidal) where possible.

- ☐ I’m limiting full-width slotting and heavy “trenching” cuts on low-rigidity machines.

- ☐ I’m watching for the first signs of chatter and backing off the variables that increase load spikes (radial engagement, stickout, flute length).

- ☐ Chip evacuation is controlled (airblast, vacuum, or other method), so chips don’t recut and amplify vibration.

The Takeaway

On CNC routers, cutting performance is often limited less by spindle power and more by stability.

Flute length and unsupported tool length play a massive role in that stability, yet they are often overlooked in favor of feeds, speeds, or coatings.

Before changing any of those variables, it’s worth asking a simpler question:

Is my cutter as short and rigid as it reasonably can be for this job?

In many cases, that alone is enough to change the outcome.

FAQs

Why does flute length matter so much on CNC routers?

Flute length affects how much of the tool is unsupported and able to flex. On CNC routers, which are generally less rigid than mills, longer unsupported length can dramatically increase deflection, chatter, and vibration.

Is flute length the same as tool stickout?

No. Flute length is the cutting portion of the tool, while stickout is how far the tool extends from the collet. Both contribute to unsupported length, which is the portion of the tool that can bend under cutting load.

Why do small increases in flute length cause big changes in chatter?

Tool deflection increases with the cube of the unsupported length. In practical terms, doubling the unsupported length can reduce stiffness by roughly eight times, making the tool far more prone to vibration.

Should I always choose the shortest flute length possible?

You should choose the shortest flute length that safely clears the required depth of cut. Too-short flutes can cause shank rubbing or poor chip evacuation, while excessively long flutes reduce rigidity.

How does flute length affect surface finish?

Longer, less rigid tools are more prone to vibration and chatter, which shows up as poor edge quality and inconsistent surface finish. Shorter, stiffer tools tend to cut more smoothly and predictably.

Does reducing flute length improve tool life?

Often, yes. Increased rigidity leads to more consistent cutting forces, less vibration, and reduced edge chipping, all of which can extend tool life on CNC routers.

How does flute length interact with flute count?

Multi-flute tools are more sensitive to rigidity issues. Shorter flute lengths help stabilize 2- and 3-flute cutters, while longer flutes can amplify vibration, especially on lower-rigidity machines.

Why do some users report better results with short, larger-diameter tools?

Increasing tool diameter improves rigidity, and pairing that with short flute length further reduces deflection. On routers, this often allows higher feed rates and better finish without increasing chatter.

Are short flutes always better for aluminum?

Short flutes improve rigidity, but adequate flute length is still needed for chip evacuation and toolpath clearance. The goal is balanced flute length, not the absolute shortest option.

Can toolpath strategy reduce rigidity problems?

Yes. Constant-engagement or adaptive toolpaths reduce sudden load spikes and work especially well with short, rigid tools on CNC routers.

Should I change feeds and speeds before addressing flute length and stickout?

It’s often more effective to address rigidity first. Many cutting issues improve immediately when unsupported tool length is reduced, making feeds and speeds easier to dial in afterward.