Sanding Smarter: Amana Tool® CNC Orbital Sander is a Gamechanger

Why Sanding Matters

Sanding is the one woodworking task almost everyone dreads. Yet it can make or break the final look of your project. A flawless build still looks unfinished if sanding leaves uneven surfaces, visible swirls, or blotchy finishes. Sanding the right way—with the right tools—turns this tedious step into a fast, precise, and even satisfying part of the process.

Sanding Basics: What Every Woodworker Needs to Know

- Abrasives matter: Most woodworking sandpaper is aluminum oxide for its durability and consistent cut. Silicon carbide, often in finer grits, excels for resin and finishing work.

- Grit progression: Never jump more than 50% in grit size (80 → 120 → 180). Each grit should erase the scratches left by the one before it.

- Technique counts: Use light, even pressure, make steady passes, and clear dust between grit changes to avoid “pig-tails” or deep scratches.

- Finish dictates grit: Film finishes like polyurethane often stop at 180 grit, while penetrating oils benefit from sanding up to 220–240.

- Don’t skip hidden areas: People notice rough edges and undersides when they touch them, even if they don’t always see them.

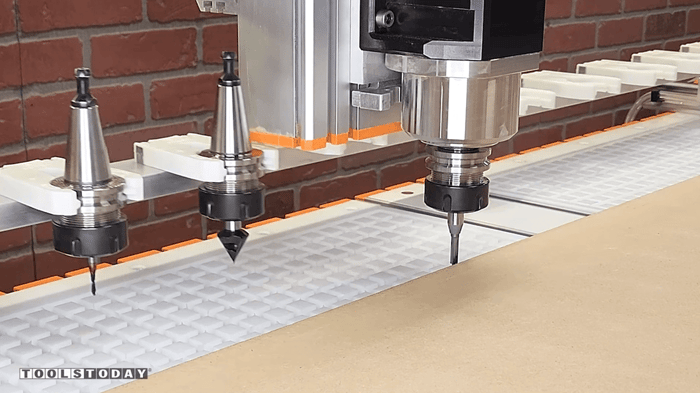

The CNC Revolution: Amana Tool® 61299 IN-SAND™

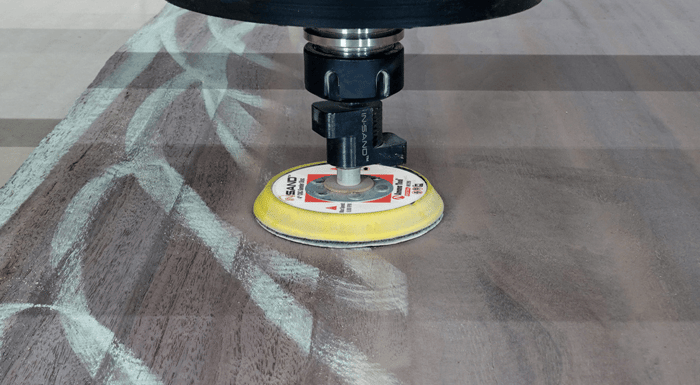

In production environments, sanding can eat up hours of valuable shop time. The Amana Tool® 61299 IN-SAND™ CNC Sander takes that burden off your team and automates it, delivering perfectly even surfaces every time.

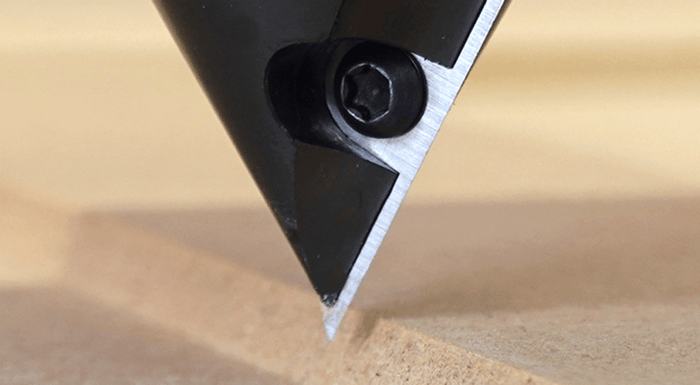

- Precision-engineered for CNC efficiency: A 4" dynamically balanced head with a 3.5mm orbital stroke sands wood and resin surfaces quickly and uniformly.

- Labor-saving in production: Automates hours of repetitive hand-sanding, freeing up skilled labor for other tasks.

- Smooth operation: Dynamic balancing minimizes vibration, improves finish consistency, and prolongs CNC spindle life.

- Flexible setup: Fits most CNC machines with a 1/2" shank.

- Consumables: Uses 4" hook-and-loop sanding discs—80 & 120 grit available. Replacement pads (Item 61299-Pad-4) are sold separately, and any Velcro-backed 4" disc can work.

- Ideal applications: Cabinet doors, sign-making, resin inlays, and flat panel finishing—all benefit from automated, consistent sanding.

Bottom line: For professional shops and small manufacturers, the IN-SAND™ transforms sanding into a CNC-controlled, repeatable process that saves time and improves finish quality.

The IN-SAND CNC Sander includes 10pcs 80 grit and 10pcs 120 grit sandpaper discs

The IN-SAND CNC Sander includes 10pcs 80 grit and 10pcs 120 grit sandpaper discsHandheld Sanding: When a Cordless Random Orbital Wins

For hobbyists or one-off builds, a high-quality handheld sander like the Festool 576822 Cordless ETSC 125 may make more sense.

- Lower upfront investment: Ideal if your sanding volume doesn’t justify a CNC setup.

- Flexibility: Perfect for irregular shapes, edges, and sculpted pieces that a CNC can’t easily reach.

- Pro-level results: Festool’s cordless design offers excellent dust extraction and a consistent scratch pattern.

Best practices still matter: avoid pressing too hard, use dust extraction, and always hand-sand with a block for the final grit to erase swirl marks.

Which Is Right for You?

- Choose CNC (Amana IN-SAND™) if you run production batches, want to eliminate hours of manual sanding, and value precision, consistency, and reduced labor costs.

- Choose Handheld (Festool ETSC 125) if you build one-offs, value flexibility, and prefer a lower-cost option without CNC setup.

Pro Tips for Better Sanding

- Let the tool do the work: Whether CNC or handheld, avoid pressing down too hard—excess pressure causes swirl marks and premature wear.

- Don’t skip grits: Each grit removes the scratches of the one before it. Jumping too far ahead means more time and more sandpaper wasted.

- Keep it clean: Dust between grit changes can create deep scratches. Always vacuum or blow off the surface before moving up.

- Finish with a light touch: A final pass by hand with a sanding block and your last grit removes machine marks for a flawless surface.

Takeaway

Whether you automate sanding with the Amana Tool® 61299 IN-SAND™ CNC Sander or perfect it by hand with a cordless Festool, understanding sanding fundamentals is key. A flawless finish isn’t about working harder—it’s about sanding smarter.

FAQs

What makes the Amana Tool® 61299 IN-SAND™ CNC Sander different from a random orbital sander?

The IN-SAND™ is a non-random orbital CNC sander that uses a precisely balanced 3.5mm orbital stroke to deliver uniform, repeatable results on wood and resin. Unlike a handheld sander, it mounts in your CNC router, automating the sanding process and eliminating hours of manual labor.

Can I use any sanding discs with the 61299 IN-SAND™?

Yes. The tool uses 4" hook-and-loop sanding discs. Amana offers discs in 80 and 120 grit, and replacement pads (Item 61299-Pad-4) are available, but any general-purpose 4" Velcro-backed disc should work.

Does a CNC sander completely replace hand sanding?

Not always. The IN-SAND™ dramatically reduces labor on flat panels, cabinet doors, and resin surfaces, but final detail sanding by hand may still be needed on edges, curves, or highly contoured areas for a perfect finish.

What’s the best grit progression for CNC sanding?

For most woodworking projects, start with 80 grit to flatten and remove machining marks, then move to 120 grit for smoothing. For projects that will receive penetrating finishes, an additional pass at 180 or 220 grit may be ideal. Always progress gradually—don’t skip grits—to avoid deep scratches.

Who benefits most from the Amana 61299 IN-SAND™?

This CNC sander is a game-changer for professional shops and small manufacturers who handle production batches or repeat jobs. It saves time, reduces labor costs, and improves consistency, making it ideal for cabinetmakers, sign-makers, and resin inlay specialists.