CNC Guide for Cabinetmakers: Best Bits for Doors, Dados, & Edge Bands

Table of Contents

- Why CNC Matters for Cabinetmakers

- Key Benefits of CNC in Cabinetmaking

- Essential Machines for CNC Cabinet Shops

- Software You’ll Need

- Best CNC Router Bits for Professional Cabinet Shops

- Best CNC Doormaking Router Bits

- Non-CNC Router Bits for Cabinetmaking

- Pro Tips for CNC Cabinetmaking

- Bringing It All Together

- FAQs

Why CNC Matters for Cabinetmakers

Computer Numerical Control (CNC) has reshaped modern cabinetmaking. Instead of measuring, marking, and cutting by hand, CNC machines follow precise, computer-generated toolpaths. Every dado, pocket, and cutout comes out exactly as designed—no guesswork, no wasted material.

For cabinetmakers, CNC means higher productivity and accuracy without compromising craftsmanship.

Key Benefits of CNC in Cabinetmaking

- Faster Production – Jobs that once took hours can now be cut in minutes.

- Perfect Repeatability – Every part is identical, critical for flat-pack cabinetry and large runs.

- Lower Labor Costs – One operator can run multiple machines, freeing skilled workers for finishing.

- Design Freedom – Intricate joinery, curved edges, and complex patterns are all within reach.

As one pro put it: “Cabinetmaking is 80% getting good, repeatable cuts.” CNC makes that a given.

Essential Machines for CNC Cabinet Shops

Using a CNC router in your shop does not mean you don't need other tools. It does mean you'll speed production and reduce labor cost, with better quality. That said:

- CNC Routers – The backbone of cabinetmaking; ideal for panels, dados, rabbets, and joinery.

- Routers - For profiles and edge-trimming.

- With a Router Table. Large profile bits should not be used in a handheld router.

Optional Machines

- Joinery Machines – Domino and biscuit cutters create strong, invisible joints quickly.

- Panel Saws – Break down sheet goods accurately before routing.on a smaller CNC machine.

- Edgebanders – Save hours finishing exposed plywood or MDF edges.

Software You’ll Need

- CAD (Computer-Aided Design) – For creating cabinet and part layouts. Most CNC machines include basic CAD, but many shops upgrade to more powerful suites for complex work.

- CAM (Computer-Aided Manufacturing) – Turns your CAD designs into precise machine toolpaths

Integrated CAD/CAM systems, like Vectric®, minimize errors and keep your workflow efficient.

Best CNC Router Bits for Professional Cabinet Shops

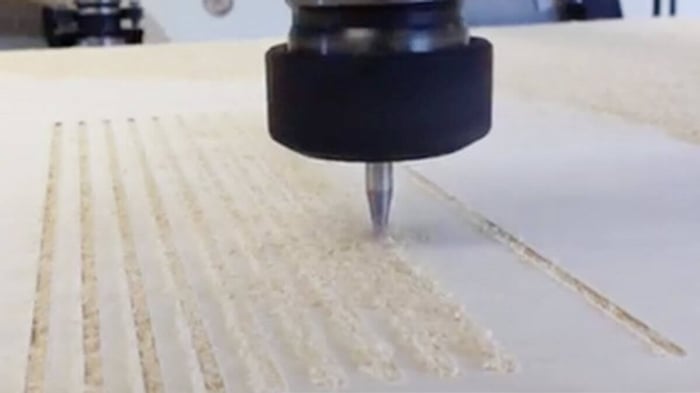

If your cabinet shop runs high-volume nested-based manufacturing, you need bits that can keep up. Amana Tool® In Presta™ High-Production Straight Plunge Router Bits are built for speed, efficiency, and long-lasting performance—cutting ¾" material in a single pass at up to 800 IPM.

With ultra-hard micro-grain carbide, precision grinding, and a compact cutting diameter that minimizes waste, these bits are engineered to fly through MDF, particleboard, plywood, and solid wood with clean, accurate cuts — day after day.

Best CNC Doormaking Router Bits

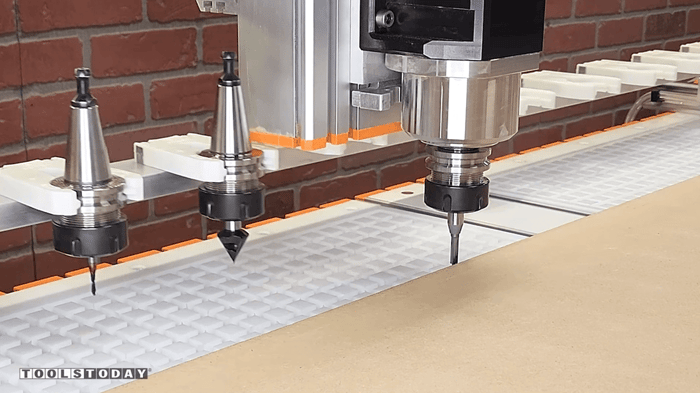

If you’re cutting MDF or wood cabinet doors on a CNC, you need precision, flexibility, and durability built into every pass. That’s where the Amana Tool® Nova System™ Plunge Form & Door Edge Insert Bits shine.

These aren’t your average door bits. Each Nova bit features replaceable carbide insert knives—so you can change profiles or refresh your cutting edge without changing the whole tool. That saves you time and money while unlocking a huge range of decorative profiles from just one bit body.

Perfect for raised panels, MDF doors, or custom wood detailing, Nova insert bits are the best CNC doormaking router bits for busy shops that demand performance, consistency, and a cleaner workflow.

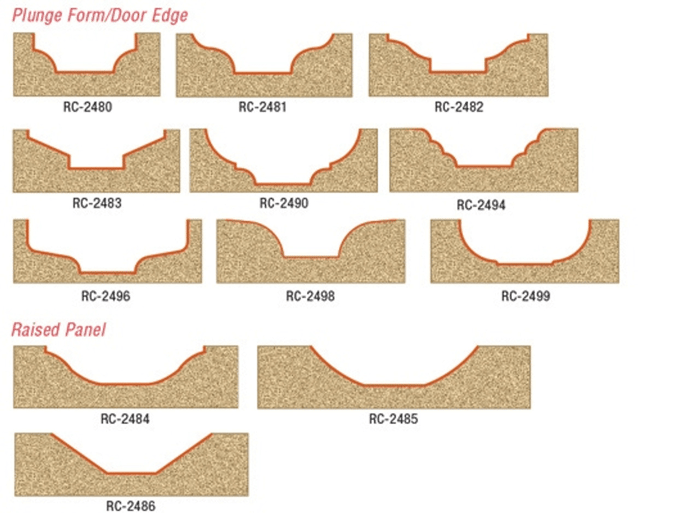

28 profiles are available for the Nova System™.

28 profiles are available for the Nova System™.

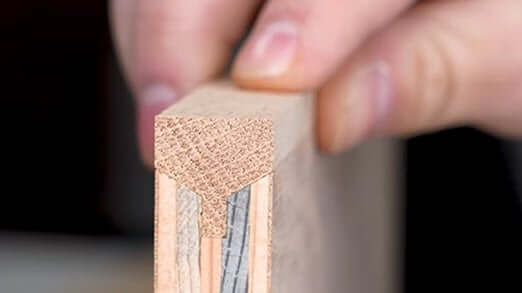

Replacement knives are Solid MDF Grade Carbide and will last much longer than standard brazed carbide tipped bits. Knives can be re-sharpened multiple times without affecting the original profile.

Interchangeable Replacement Blades for Nova System™ Plunge Type "B" CNC Router Bits (with 1/2" shank) include the RC-2480 bead; RC-2481 ogee; RC-2482 ogee; RC-2483 "traditional;" RC-2490 cove & bead; RC-2496 ogee; RC-2499 classical cove; RC-2484 ogee raised panel; RC-2485 cove raised panel; & RC-2486 "traditional" raised panel -- sold in packs of 2.

Get started with a set including Type B / CNC Plunge 1/4" Shank Body, two V-groove replaceable knives, one Core Box replaceable knife, all necessary tools to change knives, and an instructional CD.

Non-CNC Router Bits for Cabinetmaking

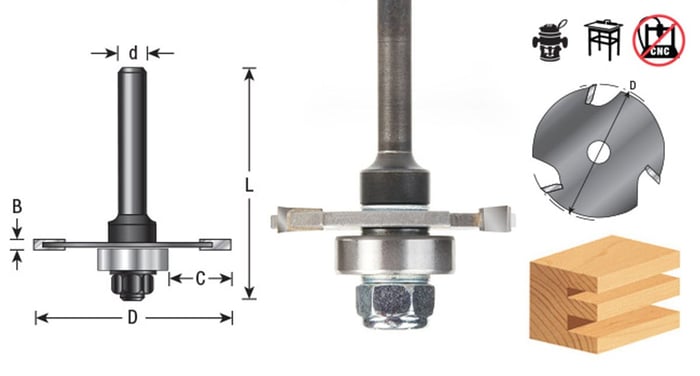

Slot Cutting Bits (Table Mount or Handheld)

Need biscuit slots or clean edge grooves? Slotting cutters still have a place in modern cabinetmaking.

These 2-wing or 3-wing assemblies come with the arbor, cutter, and bearing you need for accurate ½" deep slots. Use them in handheld or table-mounted routers to prep panels for joinery that holds up in the real world.

They’re fast, reliable, and built to last—even if they don’t ride on your CNC.

Edge Banding Bit Sets (Table Mount Only)

For cabinets with solid wood edging, these 2-piece edge banding bit sets make tight, clean-fitting joints a breeze.

They’re designed to match edge banding to panel faces with precision—no gaps, no extra sanding. Whether you’re working in maple, walnut, or birch, the results are strong, seamless, and ready for finishing.

Clean edges matter. These bits make it easy to deliver.

Some see edge banding as tedious; others see it as a mark of quality. With the right bits, the results speak for themselves.

Some see edge banding as tedious; others see it as a mark of quality. With the right bits, the results speak for themselves.Pro Tips for CNC Cabinetmaking

- Pick the Right Panels – Flat, stable sheets reduce tear-out and give smoother cuts.

- Match Bits, Speeds & Feeds – Correct settings improve finish quality and extend bit life.

- Maintain & Calibrate – Regular tuning prevents costly mistakes.

- Use Nesting – Arrange parts tightly on sheets to save material and cutting time.

- Secure Your Work – Vacuum hold-downs are fast and convenient, but clamps, T-slot tables, and even double-sided tape work for smaller jobs.

- Optimize Toolpaths – Eliminate unnecessary machine moves to shave minutes off each run.

- Tab Small Parts – Keep parts stable and prevent them from flying loose.

- Plan for Dust & Waste – Good chip collection protects bits, keeps cuts clean, and improves shop safety.

Bringing It All Together

CNC gives cabinetmakers a serious competitive edge: faster production, perfect repeatability, and design freedom that used to take hours of manual work.

Invest in the right machines, software, and bits, and your CNC setup will deliver cleaner dados, stronger joinery, and edges you can be proud of—all while improving your bottom line.

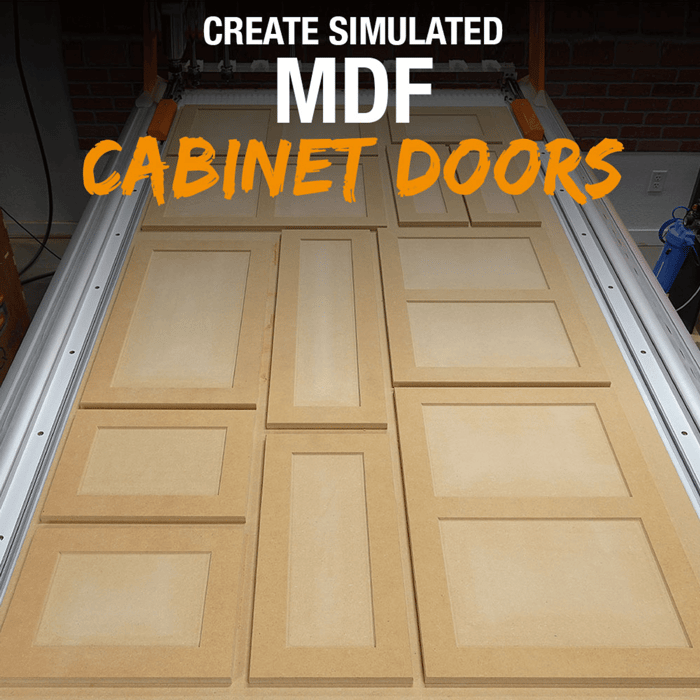

FREE Downloadable Customizable CNC Plans for Simulated Shaker Style Cabinet Doors

- See the full video now:

FAQs

How do I choose the right CNC bits for cabinetmaking?

Match the bit to the task: straight plunge bits for dados, compression bits for laminated panels, and edge banding sets for strong, beautiful edges. Premium carbide bits last longer and cut cleaner.

Is edge banding still necessary with CNC?

Yes. Plywood and MDF edges still need protection. Solid wood edge banding bits create stronger, better-looking results than peel-and-stick banding.

Do all CNC machines come with CAD software?

Most entry-level machines include basic CAD, but many pros upgrade to advanced CAD/CAM suites for more control and productivity.

Are vacuum hold-downs the only way to secure CNC parts?

No. Vacuum tables are efficient for large runs, but clamps, T-slot fixtures, and even high-strength tape can hold parts securely for smaller jobs.

How can I reduce waste when cutting cabinet parts?

Use nesting to fit parts tightly on each sheet, plan efficient toolpaths, and keep dust and chips under control to protect your bits.