Dust Extractors: Must-Have for a Clean CNC Workspace

What Are Dust Boot Systems?

Dust boot systems capture dust and debris during CNC operations, helping to maintain a cleaner workspace and protect machinery by preventing dust accumulation.

FEIN 92035236090 Turbo I Wet/Dry Dust Extractor/Vacuum Powerful wet and dry vacuum cleaner for connecting power tools during workshop and installation use.

FEIN 92035236090 Turbo I Wet/Dry Dust Extractor/Vacuum Powerful wet and dry vacuum cleaner for connecting power tools during workshop and installation use.Benefits of Dust Extraction Systems

- Improved Air Quality: Dust removal systems filter out harmful particles, reducing health risks for workers.

- Reduced Maintenance: Prevents dust buildup, minimizing machine wear and reducing downtime.

- Fire Safety: Helps prevent fire hazards associated with dust accumulation.

Improved Air Quality

Effective filtration systems capture fine particles, contributing to a healthier work environment. Poor air quality is a major cause of respiratory issues, making dust management crucial.

Reduced Maintenance and Downtime

By reducing dust accumulation, dust removal systems help prevent clogging and other issues that can lead to downtime. This results in more consistent performance and reduced maintenance costs.

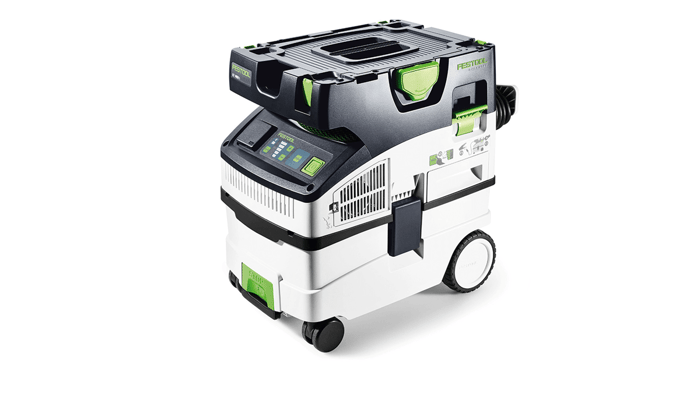

Festool 577084 Dust Extractor CT 36 E HEPA CLEANTEC Compact but large. Light but powerful. Whether it's used on the construction site or in the workshop, thanks to its huge container capacity of 36 l, the CT 36 provides maximum volume with compact dimensions.

Festool 577084 Dust Extractor CT 36 E HEPA CLEANTEC Compact but large. Light but powerful. Whether it's used on the construction site or in the workshop, thanks to its huge container capacity of 36 l, the CT 36 provides maximum volume with compact dimensions.Types of Dust Extraction Systems

There are several types of dust extractors to consider:

Portable vs. Stationary

Portable systems are ideal for small workshops or job sites, offering flexibility. Stationary systems are more suited for high-volume dust extraction in larger, fixed setups.

Single-stage vs. Two-stage

Single-stage systems are simple and cost-effective but may struggle with fine dust. Two-stage systems have pre-separators to capture larger debris, extending filter life and improving efficiency in environments with fine dust.

Choosing the Right Dust Removal System

When selecting a dust boot or extraction system, consider:

- Size and Capacity: Match the system’s capacity with your dust production to avoid overload.

- Compatibility: Ensure the system integrates seamlessly with your CNC equipment for optimal airflow and extraction.

FEIN 92030070990 Turbo II X AC PRO Set HEPA Wet/Dry Dust Extractor/Vacuum Powerful, HEPA, professional wet / dry vacuum cleaner with fully automatic filter cleaning, for attachment of various case systems, includes extensive accessories.

FEIN 92030070990 Turbo II X AC PRO Set HEPA Wet/Dry Dust Extractor/Vacuum Powerful, HEPA, professional wet / dry vacuum cleaner with fully automatic filter cleaning, for attachment of various case systems, includes extensive accessories.Installation and Maintenance

Proper installation and maintenance are crucial. Secure all fittings to avoid air leaks, and regularly clean filters to maintain peak performance. Proactive maintenance reduces the risk of system failure and extends the life of the equipment.

Cost and ROI

While the upfront cost of dust systems can be significant, the long-term savings in reduced maintenance, increased productivity, and better air quality justify the investment. A well-maintained system leads to a safer, more efficient workshop, contributing to overall operational savings.

FAQs

What are dust boot systems?

These systems capture and remove dust from the workspace of CNC machines, keeping the environment cleaner and safer.

Why are dust removal systems important?

They prevent damage to machines, improve air quality, and reduce fire hazards associated with dust accumulation.

What types are available?

Options include portable, stationary, and central vacuum systems, each suited to different workshop needs.

How do I choose the right dust removal system?

Consider the size of your workspace, type of materials processed, and dust generation level when choosing a system.

Do I need regular maintenance?

Yes, regular cleaning and filter replacement are essential for optimal performance.

Can I use these systems for other materials?

Yes, many dust removal systems work for wood, plastic, and metal, with some requiring different attachments or filters for specific materials.