Drill Bit Mastery: The Essential Guide to Selecting and Using Drill Bits

Types of Bits

There are various types of bits, including forstner bits, masonry bits, spade bits, and auger bits. Each is designed for specific materials and tasks, with coatings like titanium offering increased durability.

Materials and Coatings

Drill bits come in different materials, such as high-speed steel (HSS) and carbide. Each type offers advantages for different applications. Titanium coatings can extend the lifespan of bits, while diamond coatings are ideal for tough materials.

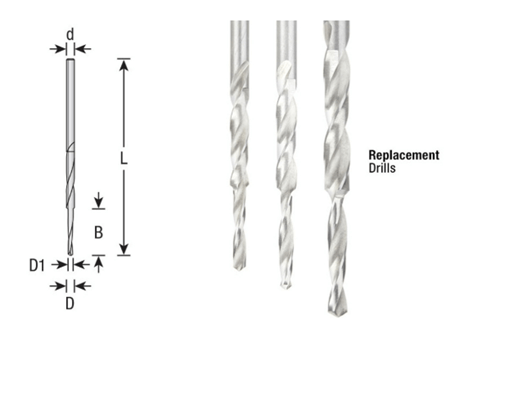

Timberline 630-016 High Speed Steel (HSS) M2 DIN 338 Fully Ground Regular Flute 3/16 D x 1 CH x 3-3/8 Inch Long Step Drill Slow Spiral, HSS M2 DIN 338 Fully Ground Step Drill Bits.

Timberline 630-016 High Speed Steel (HSS) M2 DIN 338 Fully Ground Regular Flute 3/16 D x 1 CH x 3-3/8 Inch Long Step Drill Slow Spiral, HSS M2 DIN 338 Fully Ground Step Drill Bits.Choosing the Right Bit

Selecting the right bit is crucial for achieving efficient results. Factors such as material, size, and coating play an important role in the choice. For example, masonry bits are designed for concrete, while twist bits are suitable for wood.

Factors to Consider

Consider the material you are drilling, the size of the hole, and the type of drill you're using. The right geometry and coating can ensure optimal performance for your specific application.

Using Drill Bits Safely

Always follow safety guidelines when using drill bits. Ensure that the bit is securely fastened in the chuck, and use appropriate speed and torque settings to avoid accidents and equipment damage.

Proper Techniques

When drilling, use the correct speed for the material. Too much pressure can lead to overheating, damaging both the bit and the material being drilled. Wear safety gear to protect yourself.

Maintaining and Sharpening Drill Bits

Regular maintenance is key to ensuring the longevity of your drill bits. Store them properly and sharpen them as needed to maintain their performance over time.

Tips for Longevity

Inspect your bits regularly for signs of wear. Store them in a dry, organized space to prevent rust or damage, and sharpen them as necessary to maintain efficiency.

Sharpening Methods

To sharpen a dull drill bit, use a bench grinder or sharpening stone. Proper sharpening techniques help restore the bit’s cutting ability and extend its lifespan.

Specialty Bits

Specialty bits, such as core bits and auger bits, are designed for specific tasks like drilling large holes or deep wood drilling. These bits offer precision and efficiency for specialized applications.

When to Use Specialty Bits

Use specialty bits when working with materials or tasks that require unique bit properties, like deep wood drilling or larger holes in masonry. Using the correct bit for the task will save time and improve results.

Examples of Specialty Bits

Examples of specialty bits include flat bits for shallow holes, step bits for variable sizes, and masonry bits for concrete. Each type offers advantages depending on the material and task at hand.

Amana Tool UNI-5000 5-Piece Carbide Tipped Masonry Drill Bit Set 5/32 Inch, 3/16 Inch, 1/4 Inch, 9/32 Inch, 5/16 Inch The only carbide tipped drill set for precision drilling in all materials.

Amana Tool UNI-5000 5-Piece Carbide Tipped Masonry Drill Bit Set 5/32 Inch, 3/16 Inch, 1/4 Inch, 9/32 Inch, 5/16 Inch The only carbide tipped drill set for precision drilling in all materials.Frequently Asked Questions

Why is it important to choose the right drill bit?

The right drill bit ensures precision, minimizes material damage, and helps achieve the best possible outcome for your project.

What factors should I consider when selecting a drill bit?

When selecting a drill bit, consider the material, hole size, and type of task you're performing. These factors will guide your choice of bit type and coating.

Can I use the same drill bit for all materials?

No, different materials require different bits. For example, masonry requires specialized bits, while wood can be drilled with twist or spade bits.

How do I properly use a drill bit?

Ensure the material is secure, use the correct speed for the task, and apply even pressure. This ensures both safety and efficiency during drilling.

What are some common mistakes to avoid when using drill bits?

Common mistakes include using the wrong bit for the material, not securing the material properly, or applying too much pressure during drilling.