Carbide Burr Bits for Die Grinders: How to Choose and Use Them

Burr bits are versatile and essential tools in many industries, offering precision and efficiency in cutting and shaping various materials. In this comprehensive guide, we will explore the different types of burr bits, their uses, and the compatible tools for optimal performance. From understanding the materials they can cut through to choosing the right burr bit for specific applications, we'll cover everything you need to know to make informed decisions.

We'll delve into safety measures and common mistakes to avoid when using burr bits, ensuring that you can maximize their potential while maintaining a safe working environment. Whether you're a seasoned professional or just starting, this article will equip you with the knowledge to select and use burr bits effectively.

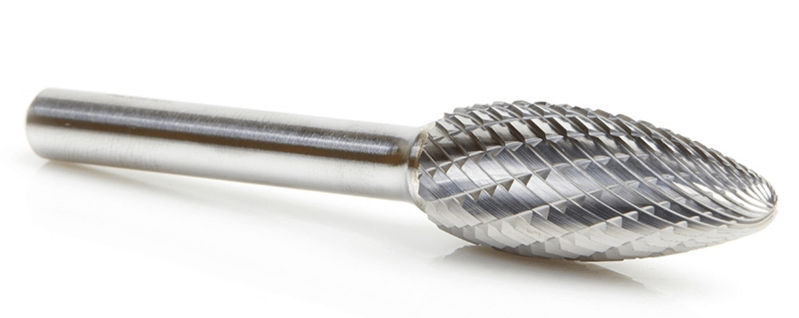

What Are Burr Bits?

Burr bits, also known as carbide burrs, are versatile tools used for cutting, shaping, and grinding various materials.

These bits are commonly employed in industrial manufacturing, metalworking, woodworking, and engineering applications due to their exceptional performance and durability. Carbide burrs are designed to effortlessly handle materials such as steel, aluminum, cast iron, wood, and plastics, making them essential for a wide range of tasks. Their ability to remove material with precision while maintaining a smooth surface finish makes them critical in intricate shaping and detailing work.

How Are Burr Bits Used?

Burr bits are used for deburring, shaping, and grinding various materials through precise motion and contact with the surface.

What Tools Are Compatible With Burr Bits?

Burr bits are compatible with a wide range of tools, including of course die-grinders, high-speed engravers, micro motors, CNC machines, and air tools, allowing for versatile applications across various industries.

When paired with high-speed engravers, burr bits exhibit exceptional precision and control, making them ideal for intricate detailing and fine work in the manufacturing and jewelry industries. Similarly, the compatibility of burr bits with micro motors enables smooth and precise material removal, creating opportunities in dental labs and electronic component manufacturing.

In the realm of CNC machines, burr bits excel in shaping and carving tasks, catering to the demands of woodworking, metalworking, and prototyping applications. Their adaptability with air tools positions burr bits as essential components in aerospace, automotive, and mold-making sectors, where efficiency and precision are paramount.

What Materials Can Burr Bits Cut Through?

Burr bits are capable of cutting through a diverse range of materials, including metals such as steel, aluminium, and cast iron, as well as wood and plastics, making them essential for various processes including chamfering, casting, and welding.

They possess the remarkable capability to swiftly and precisely cut through tough materials, such as steel and aluminium, without compromising on the quality of the cut. Their versatility extends to facilitating intricate cuts on delicate materials like wood and plastics. These properties make them critical in a multitude of applications, from shaping and chamfering edges to refining metal castings and aiding in welding processes.

What Are the Types of Burr Bits?

Burr bits are available in various shapes, with variations in cut, coatings, flute, shank, diameter, and head diameter, each designed to operate optimally within specific RPM ranges.

Double Cut Burr Bits

Double cut burr bits feature two sets of flutes and are adept at rapid material removal and increased control, with specific safety considerations and diverse applications across various materials.

These burr bits are designed to swiftly eliminate material while offering exceptional control, making them critical in tasks requiring precision and speed. Their unique double-cut design facilitates efficient chip evacuation and reduces the tendency for clogging, enhancing the overall cutting performance.

They exhibit remarkable versatility, effectively tackling materials such as wood, plastic, aluminum, and even steel. It is essential to employ the appropriate speed and feed rates to ensure optimal performance and longevity.

ZrN-Coated Burr Bits:

Material: Zirconium Nitride (ZrN) is a hard ceramic material used as a coating on carbide burr bits.

Properties: ZrN coatings offer high hardness, abrasion resistance, and can withstand high temperatures. This coating reduces friction, which in turn reduces heat generation during cutting. It also provides a lubricating effect.

Applications: ZrN-coated burr bits are ideal for non-ferrous metals like aluminum, brass, copper, and also for plastics and wood. The coating prevents the material from sticking to the bit, which is especially useful when working with softer metals and materials that tend to gum up.

Durability: The coating extends the life of the burr bit by protecting it from wear and tear. It's particularly effective in high-speed applications where heat generation is a concern.

In short, the ZrN Coating:

- Creates a harder and tougher cutting edge

- Allows for a prolonged cutting edge life

- Helps to prevent the build-up of material in the flutes while cutting

Diamond Cut Burr Bits

Diamond cut burr bits, are specifically designed for intricate work on hard materials such as metals, ceramics, and glass, making them valuable tools for applications in jewellery making and model engineering.

These specialized burr bits are known for their superior cutting performance and durability, thanks to the diamond coating. Their precise and efficient cutting action allows craftsmen and artisans to create detailed designs and patterns on hard materials with ease.

Material: These burr bits are not coated with diamond but are named for their cut style, which resembles the facets of a diamond. They have a very sharp and fine cutting edge.

Properties: Diamond-cut burr bits have a multitude of sharp, small cutting edges for removing material. They create a finer finish compared to standard or single-cut burrs.

Applications: These bits are suitable for hard materials like hardened steel, ceramics, carbon fiber, fiberglass, and other tough metals. They are also used for finishing work, providing a smoother surface finish.

Durability: While not as heat-resistant as ZrN-coated bits, diamond-cut bits are durable due to their hardened cutting edges. They excel in applications requiring fine, detailed work, and high precision.

In summary, ZrN-coated burr bits are excellent for high-speed applications, particularly with non-ferrous metals and materials prone to sticking, thanks to their heat resistance and lubricating properties.

Diamond-cut burr bits, on the other hand, are ideal for working with very hard materials and where a fine, detailed finish is required. The choice between the two depends largely on the material you are working with and the specific requirements of your project.

Burr Bit Shapes

Carbide burr bits come in various shapes, each designed for specific tasks in metalworking, woodworking, and other material processing. The shape of the burr determines its suitability for certain applications.

Cylindrical Burr Bits: These are ideal for contour finishing, flat surface removal, and working on very narrow edges. The straight sides make them suitable for working on inside corners and for flat surface grinding. Cylindrical burrs can be found with or without end cutting edges, and as flat or radius cylinder shapes.

Ball Shape Burr Bits: These are used for smoothing and shaping curved surfaces, internal contours, and round holes. Their spherical shape makes them excellent for concave cutting, hollowing out material, and creating rounded edges. They're also used in die grinders for contour finishing.

Oval Shape Burr Bits: Also known as "egg shape" burrs, these are versatile and can be used for rounding off edges and making concave cuts. They are particularly useful for die-sinking, channel work, and work on contoured surfaces.

Tree Shape Burr Bits: These burrs are pointed or rounded at the end, resembling a tree. They are excellent for channel work, making tapered holes in soft metals, cleaning corners, and accessing hard-to-reach areas. The pointed version is great for narrow areas, while the rounded version is better for a smoother finish.

Flame Shape Burr Bits: As the name suggests, these burrs resemble a flame. They are particularly useful for intricate and detailed work, including carving and sculpting. They are excellent for round-edged cuts or grooves and work well on both hard and soft materials.

Cone Shape Burr Bits: These come in different angles and are used for chamfering, countersinking, deburring, and engraving. Their conical form is suited for working on angles, grooves, and tapered holes. They offer precision and are good for detailed metal removal.

Similar to cylinder burr bits, cone shape bits come in both pointed and radius cone styles.

Each burr type has its unique application and can be selected based on the specific needs of the task at hand. For example, if you need to work on a flat surface, a cylindrical burr might be your best choice, while for detailed engraving, a flame shape or a cone shape might be more appropriate.

How to Choose the Right Burr Bit?

Selecting the right burr bit involves considering the material being worked on, choosing the appropriate shape and size, and determining the motion required for the specific application.

Consider the Material Being Worked On

When selecting a burr bit, it is crucial to consider the specific material being worked on, taking into account its properties, such as hardness, heat sensitivity, and the required motion for the cutting, shaping, or grinding process.

For example, when working with cast materials, it's important to choose a burr bit that can efficiently handle the inherent hardness and potential brittleness of the material. On the other hand, in welding applications, the burr bit must be able to withstand the heat generated during the process without compromising its cutting ability.

Diverse materials like aluminum, stainless steel, or composites will each demand different characteristics from a burr bit, considering factors such as abrasiveness, conductivity, and structural integrity.

Choose the Appropriate Shape and Size

The choice of the burr bit's shape and size is critical, as it directly impacts the precision, efficiency, and motion control during the cutting, shaping, or grinding process, offering distinct advantages for different applications.

Note that while router bits typically have shank sizes from 1/4" to 1/2" or even 3/4", burr bits can have shank size of down to 1/8", with 1/4" most common.

When selecting the shape, factors such as the material being worked on, the desired outcome, and the type of task at hand must be considered. For instance, a cylindrical burr bit is ideal for creating straight, clean edges and channels. On the other hand, a conical shape provides greater maneuverability and access to intricate areas. The size of the burr bit determines the intricacy and detail achievable in the workpiece. A smaller bit is suitable for intricate details and delicate work, while a larger bit is more efficient for bulk material removal.

Determine the Speed and Power Needed

Determining the appropriate speed and power requirements, such as RPM and pressure settings, is crucial for optimizing the performance of burr bits, especially those made of tungsten carbide, to achieve efficient motion and material processing.

In terms of RPM, it is essential to match the rotational speed to the specific material being worked on. For example, lower RPMs are suitable for softer materials like wood, while higher RPMs are necessary for harder materials like metal or stone.

Understanding the pressure settings is imperative as it directly impacts the efficiency and precision of the burr bits. Proper pressure ensures the bits can effectively cut through the material without causing unnecessary wear and tear.

Tungsten carbide, known for its exceptional hardness and heat resistance, is a key factor in the performance of burr bits. Its durability allows for sustained cutting power and precision, making it an ideal material for demanding applications.

How to Use Burr Bits Safely?

Using burr bits safely involves wearing protective gear, securing the workpiece, applying appropriate speed and pressure, and ensuring proper cleaning and maintenance after use.

Wear Protective Gear

When using burr bits, it is essential to wear appropriate protective gear to shield against potential hazards, especially related to the application of pressure during cutting, shaping, or grinding operations.

Protective gear, including safety goggles, gloves, and a face shield, helps to prevent injuries from flying debris and contact with sharp edges. For example, eye protection is crucial, as burr bits can generate tiny metal fragments that may cause eye damage. Wearing a dust mask or respirator is important to avoid inhaling particles produced during the operation, safeguarding the respiratory system. Proper footwear is necessary to protect against accidental slips or falls when using burr bits on different materials.

Secure the Workpiece

Securing the workpiece effectively before using burr bits is crucial to ensure stability and control during the cutting, shaping, or grinding process, minimizing the risk of unexpected motion or hazards.

When the workpiece is securely held in place, it allows the burr bits to operate with precision and consistency. This is particularly important when dealing with delicate materials or intricate designs where even the slightest movement can result in a flawed outcome. Securing the workpiece reduces the likelihood of accidents or injuries, promoting a safer working environment.

Whether using clamps, vices, or specialized fixtures, the proper securing method ensures that the workpiece remains steadfast, enabling the operator to focus on the task at hand.

Use Appropriate Speed and Pressure

Applying the appropriate speed and pressure in line with the specific material and burr bit type is critical to ensure efficient cutting, shaping, or grinding operations while adhering to essential safety guidelines.

When working with different materials such as wood, metal, or plastic, it's paramount to adjust the speed and pressure settings accordingly to achieve the desired results and prevent damage to the workpiece and the burr bit.

For instance, harder materials typically require lower speeds and higher pressure levels to maintain control and precision, while softer materials may necessitate higher speeds with gentle pressure to avoid over-cutting or melting.

The selection of the burr bit type must complement the material properties, influencing the optimal operating parameters. Each burr bit variant, such as diamond, carbide, or high-speed steel, requires specific speed and pressure levels for efficient performance and prolonged tool life.

Clean and Maintain the Burr Bit

Proper cleaning and maintenance of burr bits, especially those made of tungsten carbide, are essential to prolong their lifespan and optimize their performance for future use in cutting, shaping, or grinding applications.

Regular cleaning removes debris and material build-up, preserving the sharpness and integrity of the cutting edges. For tungsten carbide burr bits, which are renowned for their hardness and durability, cleaning is particularly crucial. By preventing corrosion and oxidation, proper maintenance assures that these burr bits continue to deliver precision and consistent results over an extended period of time.

What Are the Common Mistakes When Using Burr Bits?

Common mistakes when using burr bits include applying the wrong type for the material, exerting excessive pressure, and neglecting proper cooling or lubrication, which can impact both the tool and the workpiece.

Using the Wrong Burr Bit for the Material

One of the common mistakes is using an inappropriate burr bit for a specific material, which can lead to suboptimal cutting, shaping, or grinding results and affect the overall motion and precision of the process.

An incorrect burr bit can cause excessive heat buildup, leading to material burning or discoloration. It can also result in chipping or splintering of the material, compromising the surface finish. Using the wrong burr bit may increase the wear and tear on the tool, reducing its lifespan and efficiency.

Incorrect burr bit choice can impact the operator's safety, as a mismatched bit may cause erratic movements, vibrations, or even breakage during operation, posing potential hazards to the user and surrounding equipment.

Using Too Much Pressure

Exerting excessive pressure when using burr bits can result in compromised material integrity and potential safety hazards, especially during high-precision operations on various materials.

When excessive pressure is applied, the burr bits can dig too deeply or aggressively, leading to surface irregularities, weakened structural integrity, and even material fracturing. This can be particularly problematic when working with delicate materials such as ceramics or composites, where the risk of chipping or cracking is heightened.

The excessive force can also generate excessive heat, increasing the likelihood of thermal damage, melting, or altering the material's properties. Safety-wise, the potential for tool breakage or kickback during operation poses a significant risk to the operator and surrounding personnel.

Not Using Proper Cooling or Lubrication

Neglecting the application of proper cooling or lubrication during burr bit operations can lead to overheating, premature wear, and diminished performance across different materials, warranting specific attention for safety and material preservation.

When overheating occurs due to inadequate cooling, it can severely compromise the integrity of the burr bit as well as the materials being worked on, leading to reduced tool life and suboptimal results. In addition, the lack of proper lubrication can cause increased friction, resulting in excessive heat generation and potential damage to both the tool and the workpiece. This can ultimately result in increased manufacturing costs due to frequent tool replacements and material wastage, underscore the significance of adhering to cooling and lubrication guidelines for burr bit operations.