How Laser Cutters and Engravers Shape Design & Production

What Are Laser Cutters and Engravers?

Laser cutters and engravers use focused laser beams to cut and engrave materials like wood, acrylic, and metal. These tools provide precise, clean results, making them ideal for both creative and industrial applications. By adjusting lenses and settings, users can customize cut depths and engraving details based on material types.

xTool P2 55W CO2 Laser Engraver (Class 4) - With Fire Safety set Personalize almost anything quickly on-the-go!

xTool P2 55W CO2 Laser Engraver (Class 4) - With Fire Safety set Personalize almost anything quickly on-the-go!Benefits of Laser Cutters and Engravers

Laser technology offers several advantages:

- Precision: Achieve intricate cuts and engravings with high accuracy.

- Efficiency: Quickly process materials, saving time on both prototyping and production.

- Versatility: Compatible with various materials, including wood, acrylic, and metal, making it ideal for a wide range of projects.

- Customization: Perfect for creating personalized products or detailed designs for clients.

Wide Material Compatibility

Laser cutters and engravers work with diverse materials. Acrylic’s smooth finish makes it ideal for signage, while wood is perfect for custom gifts. Metals like stainless steel and aluminum can be challenging but yield impressive results for industrial and artistic uses. Adjust your settings to match the material’s thickness and properties for optimal results.

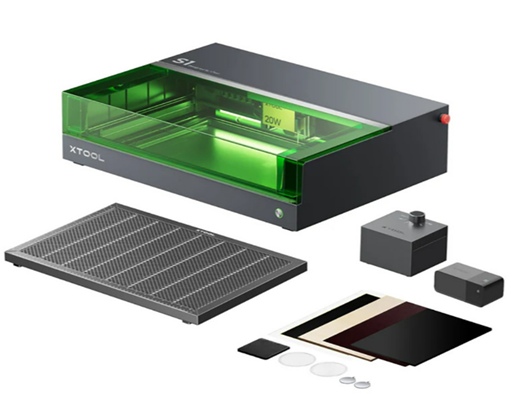

xTool S1 Enclosed Diode Laser Cutter 40W This is an all-in-one, ultra-precision laser engraver. From beginner to expert, there's something for everyone.

xTool S1 Enclosed Diode Laser Cutter 40W This is an all-in-one, ultra-precision laser engraver. From beginner to expert, there's something for everyone.Applications in Various Industries

Laser technology has wide applications, from crafting to manufacturing:

- Creative Arts: Designers use laser engraving to create intricate patterns on fabrics or jewelry.

- Manufacturing: Automakers rely on laser cutting for fast, precise parts.

- Signage: Customize signs and displays with intricate designs or logos.

- Small Businesses: Startups use these tools for efficient production and custom product offerings.

Choosing the Right Laser Cutter or Engraver

Selecting the best laser cutter or engraver depends on your needs:

- Budget: Consider the initial investment and long-term operational costs.

- Power and Speed: Higher power allows for faster processing of thicker materials.

- Software Compatibility: Ensure the machine works seamlessly with your design software.

Getting Started: Techniques and Safety

Before you begin, familiarize yourself with the basic functions of your laser cutter. Safety is paramount, so always wear protective eyewear, ensure proper ventilation, and follow manufacturer guidelines. Start with simple projects like coasters or keychains to practice your skills.

Troubleshooting Common Issues

To ensure quality results, troubleshoot common issues like misalignment, inconsistent cuts, or software glitches. Regular maintenance and calibration are essential for keeping your machine running smoothly.

FAQs

What is a laser cutter and engraver?

A laser cutter and engraver uses a laser to precisely cut and engrave materials like wood, acrylic, and metal based on computer designs.

What materials can be worked on?

Laser machines work on materials including wood, acrylic, leather, paper, cardboard, and some metals.

How do I choose the right machine?

Consider machine size, power, material compatibility, and software support when choosing a laser cutter or engraver.

What are the advantages of using a laser cutter?

Laser cutters offer precision, speed, and the ability to handle a wide range of materials with minimal post-processing.