How to Reduce Scrap in CNC Manufacturing | Boost Consistency With IN-PRESTA™ Router Bits

Table of Contents

- 1. Start With Tooling That’s Built for Predictability

- 2. Dial In Feeds & Speeds for the Material You're Cutting

- 3. Improve Workholding to Eliminate Part Movement

- 4. Standardize Toolpaths for Repeatability

- 5. Track Tool Life Before Quality Drops

- 6. Reduce Scrap by Improving Chip Evacuation

- 7. Standardize Operator Procedures

- Final Thoughts

- FAQs

For small CNC manufacturing shops running routers day in and day out, scrap isn’t just waste — it’s lost time, lost material, and lost margins. Whether you're building short-run components, cabinet parts, or custom fixtures, every rejected piece eats into profits and disrupts workflow.

Fortunately, most scrap isn’t random. It’s predictable, preventable, and often caused by a small number of controllable factors: tool condition, feed/speed errors, workholding issues, and programming mistakes. And one of the most effective levers for controlling all of these is your cutting tool — specifically the quality, geometry, and reliability of the router bit itself.

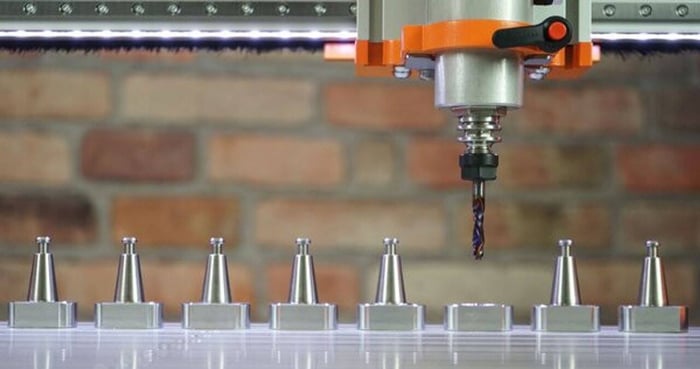

This is where IN-PRESTA™ CNC Router Bits come into play. These high-production bits are engineered to deliver consistent results across long cycles, helping small shops cut cleaner, reduce tool-related rejects, and standardize quality even across multiple machines or operators.

1. Start With Tooling That’s Built for Predictability

The fastest way to reduce scrap is to eliminate inconsistent cutting performance. Low-grade bits dull quickly, burn material, wander off the toolpath, or leave chipped edges — all of which lead to rejects.

IN-PRESTA™ CNC Router Bits are designed specifically for high-production, small-batch, and repeatable manufacturing. Their precision-ground carbide, stable geometry, and balanced construction help maintain edge quality far longer than standard bits.

Consistent edge quality = consistent parts

- Cleaner edges with less post-processing

- Reduced tear-out on plywood and composites

- More accurate pockets and profiles

- Repeatable dimensional accuracy across multiple units

2. Dial In Feeds & Speeds for the Material You're Cutting

The second leading cause of scrap is incorrect chip load — either too high (breakage, tear-out) or too low (heat, burning, premature dulling). Even a perfect bit can perform poorly if it’s not run at the correct parameters.

To optimize:

- Set spindle RPM to match the material and bit diameter

- Adjust feed rate to achieve ideal chip size (not dust, not chunks)

- Increase plunge rates only when the bit is designed for aggressive entry

- Use test cuts before committing to full-sheet runs

High-production tools like IN-PRESTA™ are engineered to run at efficient chip loads without degrading edge life. If you’re cutting hardwood, laminates, or composites, the right feed/speed combination can extend bit longevity dramatically, which not only reduces scrap — it reduces tool spend.

3. Improve Workholding to Eliminate Part Movement

Part movement is one of the most painful causes of rejects, because it can destroy a component even when the program and tooling are perfect.

Strengthen workholding by:

- Using a well-maintained vacuum table with clean spoilboards

- Confirming vacuum zoning is appropriate for the part size

- Eliminating leaks around gasket tape

- Using additional clamps for small parts or narrow profiles

- Routinely resurfacing the spoilboard for flatness

Even a slight shift during machining can lead to misalignment, chatter, or edge blowout. When the part is locked down securely, tooling performs dramatically better and dimensional accuracy increases.

4. Standardize Toolpaths for Repeatability

Program variation is another subtle source of scrap — especially in small shops where different operators create toolpaths in slightly different ways.

To reduce rejects:

- Use consistent lead-ins/lead-outs across similar jobs

- Apply the same finishing pass strategy for recurring parts

- Store validated toolpath templates in your CAM library

- Always simulate tool movement before running new code

A well-designed CAM strategy paired with a predictable tool like the IN-PRESTA™ makes part quality highly repeatable, even across shifts or teams.

5. Track Tool Life Before Quality Drops

Instead of waiting for a bit to fail or chatter, implement a basic tracking system:

- Log start/end hours for each bit

- Track material type and job count

- Inspect the cutting edge every X sheets or every X hours

- Replace tools based on performance, not just appearance

High-performance tools like IN-PRESTA™ make this even easier because their wear patterns are predictable. If a bit normally lasts 60 sheets of MDF, you can confidently swap it at 55 and never risk a scrap event.

6. Reduce Scrap by Improving Chip Evacuation

Poor chip evacuation leads to heat buildup — and heat kills bits.

Improve chip evacuation by:

- Using dust collection that matches the machine’s CFM needs

- Keeping flutes clean between cycles

- Ensuring extraction paths aren’t blocked

- Using compressed air blast or mist coolant for tough composites

The precision-ground flutes on IN-PRESTA™ bits help maintain clean chip flow, but evacuation still has to be managed at the system level.

7. Standardize Operator Procedures

Create a checklist for:

- Zeroing the machine the same way every time

- Tool length measurement

- Material loading

- Vacuum engagement

- Running a simulation before cutting

- Verifying cutter selection

When the process is consistent, part quality becomes consistent.

Final Thoughts

Scrap is costly — not only in materials, but in lost production time. The good news? Most scrap in CNC manufacturing comes from predictable, fixable issues.

Small manufacturers who rely on:

- High-quality, consistent router bits such as IN-PRESTA™ CNC Router Bits

- Correct feeds and speeds

- Strong, repeatable workholding

- Standardized toolpaths and operator procedures

can dramatically reduce rejects and boost profit margins.

Better tooling doesn’t just cut cleaner — it helps your entire workflow run smoother. By upgrading the cutting tools that touch every single part, you create a foundation for consistency that ripples through your entire operation.

FAQs

What causes most scrap in CNC manufacturing?

Most scrap comes from dull tooling, incorrect feeds/speeds, part movement, poor chip evacuation, and inconsistent programming or operator workflow.

How can router bits reduce rejects in CNC production?

High-precision bits like IN-PRESTA™ maintain edge quality longer, cut cleaner, and produce repeatable geometry, which reduces tool-related scrap significantly.

How often should I replace CNC router bits?

Track hours, sheets cut, and material type. Replace bits before performance drops — not after visible wear — to prevent scrap events.

Does workholding affect scrap rates?

Yes. Even slight part movement can ruin a job. A strong vacuum table, clean spoilboard, good zoning, and supplemental clamps all reduce rejects.

How do feeds and speeds affect scrap levels?

Incorrect chip loads cause burning, chipping, tear-out, and premature tool wear. Proper feeds and speeds improve cut quality and reduce waste.