Expert's Guide to Drum Sanders

Drum sanders are powerful tools designed to smooth and finish surfaces with precision.

This article explores the different types of drum sanders, their applications, and provides a step-by-step guide on using one effectively. It also offers tips for maximizing efficiency, safety precautions, and maintenance advice to keep your drum sander in top condition.

What is a Drum Sander?

A drum sander is a woodworking tool designed for sanding and achieving a smooth finish on materials like hardwood and plywood. It's ideal for projects requiring a high-quality finish.

Drum sanders are versatile, handling everything from refinishing furniture to prepping large panels. Unlike belt sanders, which are more aggressive and can leave marks, drum sanders provide a uniform finish thanks to adjustable sanding cycles and the ability to choose the right grit for the job.

Drum sanders efficiently handle larger surfaces through continuous material feeding. Maintenance is straightforward, mainly involving the replacement of worn sanding drums. In comparison to oscillating sanders, which are better for detailed work, drum sanders excel in managing broader applications, making them a staple in many woodworking shops.

The JET JWDS-2550 Drum Sander delivers everything you need for an effortless finish. The worktable is easily positioned by a turn of the parallelism dial.

The JET JWDS-2550 Drum Sander delivers everything you need for an effortless finish. The worktable is easily positioned by a turn of the parallelism dial.

Types of Drum Sanders

Drum sanders come in several types, each suited for specific woodworking needs. Benchtop models are perfect for smaller projects, while floor models are designed for larger industrial applications.

Benchtop vs. Floor Models

Benchtop drum sanders are compact and portable, ideal for hobbyists or small woodworking shops. Floor models, on the other hand, offer more power and larger sanding capabilities, suitable for industrial applications and extensive woodworking projects.

Choosing the right sander depends on your workspace and project scale. Benchtop models, with their smaller drum size, are easier to move but limited in the width of material they can handle. Floor models offer greater efficiency for larger stock but require more space and a more permanent setup.

The JBOS-5 Benchtop Spindle Sander has a powerful 1/2HP induction motor and a large 14-1/2” table that tilts to 45° which easily handles the toughest sanding projects.

The JBOS-5 Benchtop Spindle Sander has a powerful 1/2HP induction motor and a large 14-1/2” table that tilts to 45° which easily handles the toughest sanding projects.

Common Uses of Drum Sanders

Drum sanders are essential in woodworking for surface preparation, furniture refinishing, and material removal. They ensure high standards in woodworking projects, making them a critical component of any wood shop.

Woodworking and Other Applications

In woodworking, drum sanders are indispensable for everything from DIY home improvement to professional construction work. They offer unmatched efficiency and the ability to achieve smooth, high-quality finishes.

These tools are also crucial in restoration projects, where maintaining the original material's integrity is key. Whether restoring worn furniture or preparing old wood floors for a new finish, drum sanders ensure every surface is thoroughly prepared.

Beyond woodworking, drum sanders are useful in industries like automotive and musical instrument crafting, where fine finishing is essential. Incorporating drum sanders into your workflow can significantly boost productivity and deliver exceptional results.

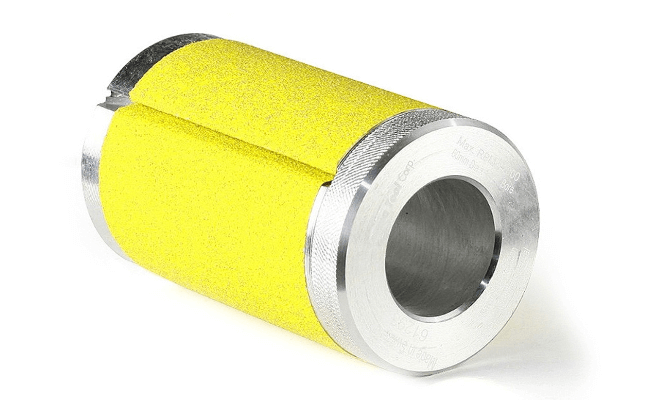

The Amana Tool 61293 Sanding Drum for 1-1/4" Bore Shaper Cutters features replaceable abrasive material (9" x 3") and an optional ball bearing rub collar.

How to Use a Drum Sander

Using a drum sander effectively requires understanding its operation and following a structured usage guide. This includes setup, calibration, and necessary adjustments to achieve optimal results.

Step-by-Step Guide

Assemble the machine according to the manufacturer's instructions, ensuring the drum is aligned and the sandpaper securely attached.

Select the appropriate grit based on the material. Use finer grits for finishing and coarser grits for shaping.

Maintain steady, even pressure as you guide the sander across the surface for smooth and uniform results. Regular maintenance, like cleaning the drum and inspecting the sandpaper, extends the equipment's lifespan.

Always prioritize safety. Wear dust masks and goggles, and be mindful of the sanding limits to avoid damaging the material.

Tips for Using a Drum Sander

To maximize efficiency and quality, implement practical tips and best practices throughout the sanding process.

Maximizing Efficiency and Quality

The choice of sanding patterns significantly impacts performance and finish quality. Techniques like cross-grain sanding or circular motions can enhance material removal or improve the surface finish depending on the wood grain and imperfections.

Grit selection is crucial. Finer grits provide smoother finishes, while coarser grits are better for aggressive sanding. The drum size also matters; larger drums cover more surface area quickly but require careful handling to prevent gouging.

4″ x 36″ Sanding Belt 180 grit (PK2)

Safety Considerations

Prioritizing safety when using a drum sander is essential to create a secure and efficient working environment, protecting both the operator and the machine.

Precautions to Take When Using a Drum Sander

Ensure the machine is in good condition and wear appropriate protective gear. Familiarize yourself with the user manual and perform regular maintenance, such as inspecting belts and rollers, lubricating components, and keeping the machine clean to prevent dust accumulation.

Secure the workpiece properly and use a dust collection system to minimize airborne particles, contributing to a healthier working environment.

Maintaining and Cleaning Your Drum Sander

Proper maintenance and cleaning of your drum sander are vital for ensuring its longevity and optimal performance.

Proper Care and Maintenance Tips

Regularly clean and inspect key components like the drum and sanding pads. Worn pads can lead to uneven surfaces and strain the machine, so replace them as needed. Check the dust collection system frequently to avoid blockages, which can hinder extraction efficiency.

Routine inspections should also include checking belt tension and alignment, allowing for adjustments that enhance smooth operation. Following these recommendations will maximize the effectiveness and lifespan of your equipment.

Frequently Asked Questions

What is a Drum Sander?

A drum sander is a power tool used for sanding and smoothing wood surfaces. It consists of a rotating drum covered in sandpaper, which can be adjusted to different speeds and levels of coarseness.

What is a Drum Sander Used For?

A drum sander is primarily used for sanding large, flat wood surfaces such as floors, tabletops, and doors. It can also be used for removing old paint or finishes, leveling uneven surfaces, and creating a smooth surface for staining or painting.

How do I Use a Drum Sander?

First, make sure to read the user manual and wear protective gear such as goggles and a dust mask. Then, adjust the sandpaper to the desired coarseness and attach it to the drum. Turn on the sander and guide it in the direction of the wood grain, keeping a steady pace and applying even pressure. Remember to empty the dust collection bag regularly to prevent clogging.

Can I Use a Drum Sander on Any Type of Wood?

No, a drum sander is not suitable for all types of wood. It is best used on hardwoods such as oak, maple, and cherry. Softer woods like pine and cedar may become damaged or splintered by the rotating drum. It is always recommended to test the sander on a small, inconspicuous area first.

What are the Benefits of Using a Drum Sander?

A drum sander provides a much more efficient and consistent sanding result compared to hand sanding. It also saves time and effort, as the machine does the work for you. Additionally, it can remove a significant amount of material in a short amount of time, making it ideal for larger projects.

Are There Any Safety Precautions I Should Take When Using a Drum Sander?

Yes, safety should always be a top priority when using power tools. Make sure to wear protective gear, keep long hair tied back, and avoid loose clothing. Keep the sander away from your body and maintain a firm grip on the machine. Also, be sure to unplug the sander when changing sandpaper or making adjustments.