Beginner’s Guide to CNC Software (for SketchUp Users)

Table of Contents

- From Virtual to Physical

- Part 1 — CAD: Your SketchUp Skills, Applied

- Part 2 — CAM: Turning Models into Toolpaths

- Part 3 — G-Code & the Controller (Sender)

- File Types You’ll Actually Use

- Shapeoko Quick-Start (Carbide Create)

- Which Software Should You Use? (4 Quick Cards)

- Toolpaths, Explained Simply

- Practice Without the Pain

- Fastest Path from SketchUp to First Cut

- FAQs

If you’ve ever modeled a cabinet, sign, or a whole house in SketchUp, you already understand the hardest part of CNC: turning ideas into accurate geometry. This guide bridges what you know in SketchUp to the CNC workflow so your virtual designs become real parts.

From Virtual to Physical

Think of the CNC process as SketchUp with power tools. You still design, but now you’ll add two new steps that tell your machine how to cut your design.

- CAD: The design stage (what you already do in SketchUp).

- CAM: The translator that creates cutting instructions from your design.

- Controller/Sender: The “pilot” that sends those instructions to your CNC.

Part 1 — CAD: Your SketchUp Skills, Applied

In CNC, “CAD” is where your model takes shape. If you’re happy designing in SketchUp, keep using it for concepting and layout. For production parts, many users move to CAD that’s built for manufacturing (e.g., parametric CAD) because it’s faster to update dimensions later.

Key upgrades vs. SketchUp

- Parametric edits: Change a value (e.g., width = 610 mm) and the model updates—no re-push/pull.

- Manufacturing-ready geometry: Clean vectors and solids reduce CAM headaches.

- Integrated workflow (Fusion 360): Design and toolpath in one place if you prefer an all-in-one tool.

Exporting from SketchUp for CNC

You can’t send a .skp file directly to a CNC. Export to formats CAM apps understand:

- 2D parts, signage, inlays: Export vectors as

.SVGor.DXF. - 3D reliefs and organic shapes: Export a mesh as

.STL.

Part 2 — CAM: Turning Models into Toolpaths

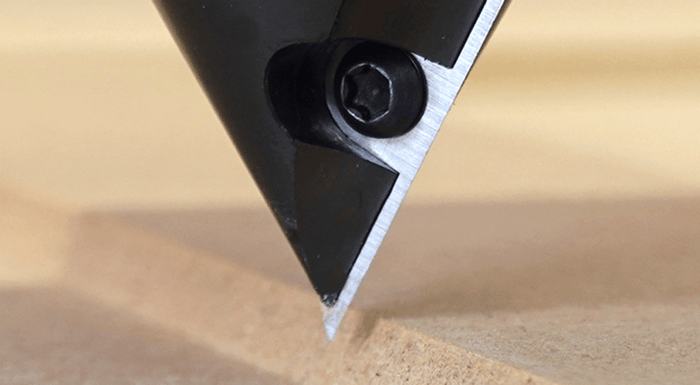

CAM is the new piece for most SketchUp users. Here you choose the cutter (end mill), feeds/speeds, and strategies. The CAM software generates a toolpath—the precise route your bit will take—and outputs G-code for your machine.

SketchUp → CAM: mental translations

- Edges & faces → Profiles & pockets: Cutting on/inside/outside a line (profile) or clearing an area (pocket).

- Text & engraving → V-carve: Use a V-bit for crisp letters and decorative lines.

- Curved/relief surfaces → 3D machining: Requires Aspire or Carbide Create Pro (or comparable CAM).

- “Preview” in SketchUp → “Simulation” in CAM: Watch an animation of the cut to catch mistakes early.

Part 3 — G-Code & the Controller (Sender)

G-code is the final file CAM creates. A sender (also called controller software) opens that file, connects to your CNC, and runs the job. Typical senders are Carbide Motion (for Shapeoko), UGS, and gSender.

You don’t need to write G-code. CAM creates it for you. As you gain experience, you might glance at it for troubleshooting, but it’s optional.

Carbide Create is included with all Nomad Desktop CNC and Shapeoko CNC routers so you don't have to spend hundreds of dollars on software to go with your new machine.

File Types You’ll Actually Use

- SVG (.svg): Clean vectors for signs, outlines, logos. Imports into Vectric and Carbide Create.

- DXF (.dxf): CAD-friendly vectors for part profiles and hole patterns. Imports widely.

- STL (.stl): 3D mesh for relief carving and sculpted surfaces (Aspire, Create Pro, or equivalent).

- Vectric project files (.crv, .crv3d): Open directly in VCarve/Aspire with toolpaths ready.

Using ToolsToday downloadable plans: Plans include SVG/DXF (universal) and Vectric project files (.crv/.crv3d). Carbide Create doesn’t use .crv, but you can import the included SVG/DXF and make toolpaths quickly.

Shapeoko Quick-Start (Carbide Create)

- Start in SketchUp (optional): draw your concept; export vectors as

SVGorDXF. - Open Carbide Create: set stock size, origin (usually front-left), and units.

- Import SVG/DXF: position and scale as needed; join/open vectors if prompted.

- Choose toolpaths: Profile (inside/outside), Pocket, Drill, or V-Carve; pick the bit and set depth.

- Simulate: preview the cut; check order, depths, and tabs.

- Post G-code: save the file and open it in Carbide Motion.

- On the machine: set zero (X/Y/Z), secure stock, run the file, watch the first pass.

Which Software Should You Use? (4 Quick Cards)

Vectric (VCarve Desktop, VCarve Pro, Aspire)

Why SketchUp users like it: Superb 2D/2.5D workflow, fast toolpath setup, excellent simulation. Great for signage, trays, furniture parts.

- VCarve Desktop: Full feature set with a smaller job-size limit—ideal hobby start.

- VCarve Pro: No job-size limit + production tools (nesting). Good upgrade for larger tables/shops.

- Aspire: Everything in VCarve plus 3D relief modeling and 3D toolpaths.

File flow: Import SVG/DXF/STL → assign toolpaths → post G-code → run in your sender.

Carbide Create (Free) & Carbide Create Pro

Why SketchUp users like it: Simple, fast, and pairs perfectly with Shapeoko. Great stepping-stone from SketchUp to CAM.

- Create (Free): 2D/2.5D (profiles, pockets, V-carve) with handy simulation.

- Create Pro: Adds 3D modeling & 3D machining for reliefs and curved surfaces.

File flow: Import SVG/DXF → create toolpaths → post G-code → run in Carbide Motion.

Inventables Easel (Free) & Easel Pro

Why SketchUp users like it: Browser-based, quick setup for simple signs and 2D jobs.

- Easel (Free): Entry-level 2D/2.5D with a friendly learning curve.

- Easel Pro: Adds V-carve and more advanced features for intricate lettering and detail.

File flow: Import SVG/DXF → toolpaths → simulate → cut (many hobby CNCs supported).

Autodesk Fusion 360

Why SketchUp users like it: CAD + CAM in one app with parametric power. Best if you want precise, editable models and stay in one environment.

- Personal use: Free with limitations (fine for many hobby workflows).

- Commercial: Full features and advanced CAM for shops.

File flow: Design → switch to Manufacture workspace → toolpaths → simulate → post G-code.

Vectric makes it easy for beginners with extensive video tutorials and a Free CNC Project Library.

Vectric makes it easy for beginners with extensive video tutorials and a Free CNC Project Library. Toolpaths, Explained Simply

A toolpath is the route your cutter follows. You’ll choose:

- Operation: Profile (cut on/inside/outside), Pocket (clear an area), Drill, V-Carve, or 3D rough/finish.

- Tool & material settings: Bit type/diameter, depth per pass, feed rate, spindle speed.

- Safety & strategy: Retracts, tabs, order of operations.

Always run a simulation first—just like orbiting your model in SketchUp to sanity-check, simulation lets you catch depth mistakes, missing tabs, or wrong cut direction before you waste material.

Practice Without the Pain

- Material: Start with MDF or plywood—predictable and forgiving.

- Keep it simple: One or two operations (e.g., a pocket + profile) to learn feeds/speeds.

- Document wins: Save working toolpaths and bit settings as presets; reuse them.

- Workholding first: Clamps, double-sided tape, or vacuum—secure stock equals clean results.

Fastest Path from SketchUp to First Cut

Grab a beginner-friendly CNC plan, import the included SVG/DXF into Carbide Create or VCarve, and use the recommended toolpaths. You’ll go from concept to a clean first cut in an afternoon—without guesswork.

FAQs

Do I need to switch from SketchUp to another CAD program?

Not necessarily. Keep using SketchUp for concepting and export SVG/DXF/STL for CAM. If you want faster dimensional changes later, try an integrated CAD/CAM like Vectric® VCarve.

What sender (controller) should I use?

Use the one that pairs best with your machine. Shapeoko → Carbide Motion. Many GRBL machines → gSender or UGS.

Do I have to learn G-code to start?

No. CAM generates G-code for you. Learning G-code basics can help with troubleshooting later, but it’s optional.

VCarve Desktop vs Pro vs Aspire—how do I choose?

Desktop: great starter with a smaller job-size limit. Pro: no size limit + production tools (nesting). Aspire: adds full 3D relief modeling.

What’s the simplest first project from SketchUp?

Design a small sign or tray, export SVG, pocket the interior, profile the outside, add tabs, simulate, and cut in MDF.