3D Carving With Ball Nose Router Bits

3D carving with ball nose router bits (a.k.a. ball-end nose bits) is a process in which material is removed from a workpiece to achieve a desired three-dimensional shape or profile, typically by using a CNC (Computer Numerical Control) router or milling machine.

Here's a general overview and some considerations:

Basics of the Ball Nose Bit:

Ball nose bits have a rounded tip, which makes them ideal for carving smooth, contoured surfaces.

They come in different sizes, allowing for detailed work (smaller bits) or more aggressive material removal (larger bits).

Advantages:

Smooth Contours: The rounded shape of the bit allows it to produce very smooth contours, making it ideal for 3D carving.

Detail: When using smaller diameter ball-nose bits, you can achieve finer details in your carvings.

Versatility: Can be used for both roughing and finishing passes.

Considerations:

Stepover: This refers to the distance between successive parallel paths that the router bit takes during carving. A smaller stepover (e.g., 10% of the bit diameter) will yield a smoother finish but will take longer. A larger stepover will be faster but might require more post-processing to smooth out.

Depth of Cut: How deep the bit goes into the material in one pass. Deeper cuts can remove material faster but might strain the bit and the machine.

Feed Rate: The speed at which the machine moves the bit through the material. Faster feed rates can speed up the process but may lead to rougher finishes or even break the bit if too fast.

Spindle Speed: The RPM at which the bit rotates. Different materials and bit sizes might require adjustments in RPM.

Applications:

Sculptures: Ball nose router bits are perfect for carving detailed 3D sculptures out of various materials.

Relief Carvings: Creating raised or recessed designs on the surface of a material.

Molds and Dies: For casting or stamping applications.

Signage: 3D signs or detailed engravings.

Furniture & Cabinetry: Decorative elements and intricate designs.

Materials:

Ball nose router bits can be used on a variety of materials, including wood, MDF, plastics, foam, and even metals, depending on the bit's composition.

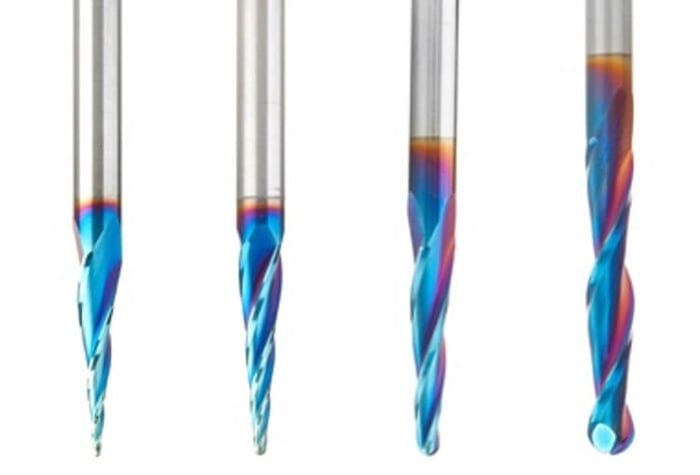

For wood, plastics, foam & more, choose Solid Carbide Spektra™ Extreme Tool Life Coated 2D/3D Carving Straight Ball Nose (Conical Ball) Router Bits with special unique carbide with nACo® nanocomposite coating for longer lifetime. The high-shear ball nose tips cut smooth 2D and 3D contours with reduced stepping while the proprietary Spektra™ coating (applied by the physical vapor deposition coating process) provides high resistance to wear sharper cutting edges extended tool life and less friction & heat buildup.

For metals, go with the CNC Ball Nose (Conical Ball) Solid Carbide Spiral 2D/3D Carving Tapered and Straight ZrN Coated Up-Cut Router Bits. The solid carbide tips cut smooth 2D and 3D contours with reduced stepping while the proprietary ZrN coating (applied by the physical vapor deposition coating process) provides high resistance to wear, sharper cutting edges, extended tool life and less friction & heat buildup.

Software:

3D carving requires CAD (Computer-Aided Design) software to design the object and CAM (Computer-Aided Manufacturing) software to translate that design into instructions (G-code) for the CNC machine.

Safety:

Always use safety equipment like goggles, ear protection, and dust masks.

Ensure the workpiece is securely fastened to the machine bed.

Always double-check the setup and do a dry run if possible to ensure the machine behaves as expected.

3D carving with ball-end nose router bits is a versatile and efficient method to create intricate 3D shapes and profiles. With the right setup, toolpaths, and attention to detail, you can achieve professional-level results.