Top 10 Tools Every Woodworker Should Have

Starting a woodworking shop is one of the most exciting—and overwhelming—steps a woodworker can take. Whether you're leveling up from a garage corner or building a pro-level workspace, the right tools make all the difference. This list isn't just about buying gear—it's about building the foundation for precision, safety, and creativity.

These are the 10 tools we believe every woodworker should have. Not necessarily the only tools, and not all at once. But each one plays a crucial role, and we’ve included our favorite models and expert tips to help you choose the best options for your shop.

1. Precision Hand Tools: Chisels

Chisels are where finesse meets force. Whether you're fine-tuning a mortise, paring down a tenon, or cleaning out dovetail sockets, a sharp chisel gives you unmatched control. For many woodworkers, they’re the first tools that make you feel like a craftsperson, not just a tool operator.

Bench chisels are your daily drivers—ideal for joinery and cleanup. The Blue Spruce Toolworks Optima Bench Chisels offer excellent edge retention and balance, with steel so hard you’ll spend more time woodworking and less time sharpening.

Want even more precision for trimming or flattening areas your chisel can't quite reach? That's where a chisel plane comes in. It works like a miniature plane with a flush-cutting blade—perfect for trimming glue joints, plugs, or uneven shoulders.

Pro Tip: Don’t cheap out on your chisels. A good set will outlast your workbench. And always hone them before first use—even premium tools need final tuning.

2. Core Shop Saw: Table Saw

If your shop were a solar system, the table saw would be the sun. It’s the tool you’ll likely build your workspace around—and for good reason. Few machines offer the same combination of power, accuracy, and repeatability for straight cuts, rips, crosscuts, and joinery setups.

While it’s possible to start woodworking without a table saw, you’ll soon hit a wall if you’re tackling cabinetry, furniture, or panel work. That’s why we recommend investing in a reliable saw from the start—and nothing offers greater peace of mind than a SawStop Contractor Saw.

SawStop saws are engineered with an active safety system that detects skin contact and stops the blade in milliseconds. It’s no exaggeration to say it can save a finger—or a career. In fact, there’s been congressional discussion about making this type of safety system mandatory across all saws in the U.S., which could change the industry standard in years to come.

Pro Tip: When setting up your table saw, start with a quality blade designed for your material and type of cut. Yes, blades matter—a lot. And yes, we’ve got plenty of them. Start here: Amana Tool Saw Blades.

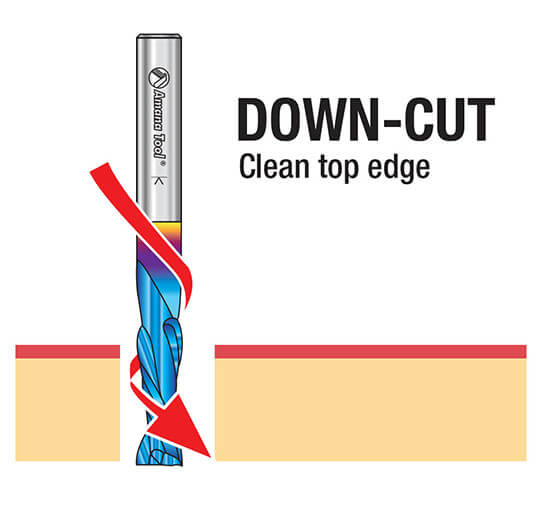

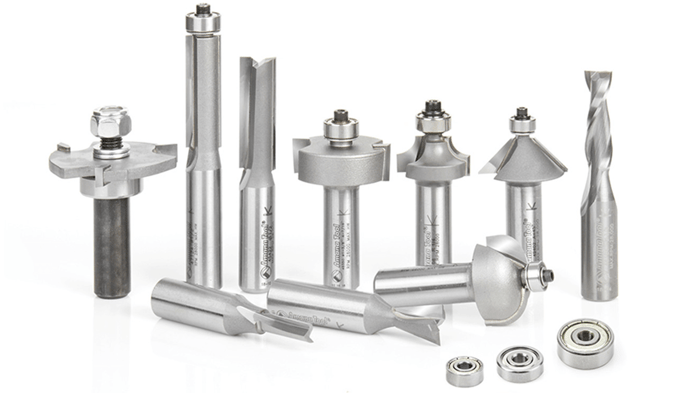

3. Router: Shaping, Joinery & Creative Edges

Routers are the most versatile cutting tools in the woodworking shop. Need to add a decorative edge? Cut joinery like rabbets or dovetails? Hollow out a recess for an inlay? The router does it all—and then some.

There are three common types of routers:

- Trim routers – Lightweight and easy to handle, ideal for edge profiling or laminate work.

- Plunge routers – Let you start cuts mid-board, like dados and mortises.

- Router tables – Mount your router upside down for precision and control with small parts or repetitive cuts.

4. Dust Collection & Shop Safety

When people think of shop safety, they usually picture goggles and earmuffs. Those are important—but the real long-term danger is dust. Wood dust is more than a nuisance: it’s flammable, airborne, and hazardous to your lungs. Even sanding soft pine can release particles that stay suspended for hours.

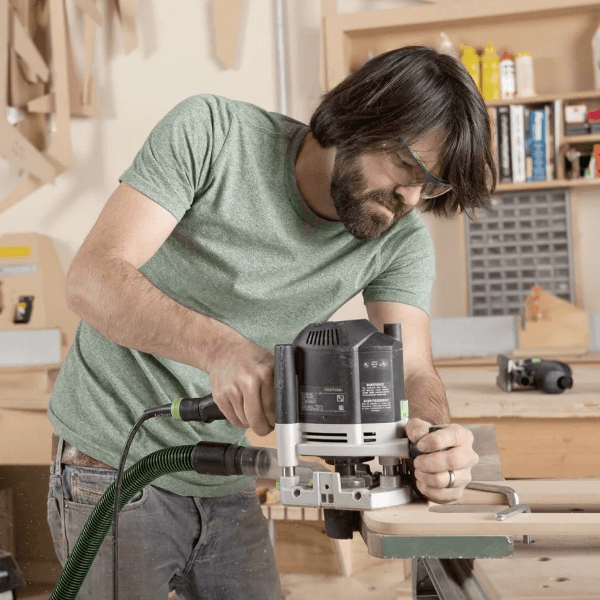

That’s why every serious shop needs a dust collection strategy. For hobbyists or small spaces, a high-quality wet/dry vacuum is often enough to get started. The FEIN Turbo I Wet/Dry Dust Extractor offers strong suction and quiet operation in a compact footprint—perfect for attaching to sanders, routers, or handheld saws.

If you’re working in a larger space or need jobsite mobility, the Festool CT MIDI I HEPA Dust Extractor is a powerful step up. With automatic tool activation, HEPA filtration, and anti-static hoses, it's the kind of tool that makes daily cleanup feel effortless.

Other safety basics still matter: quality safety glasses, ear protection, and a well-lit workspace. But don’t ignore what you can’t see. Dust is sneaky—and controlling it will protect your health, tools, and finishes.

Pro Tip: Start by connecting dust collection to your highest-risk tools—like your table saw and sander. Then add blast gates or splitters as your system grows.

5. Power Drill & Driving Tools

If you only have one power tool, it should probably be a cordless drill. From drilling pilot holes to driving screws, it's the go-to tool for everything from rough framing to finish work.

Most woodworkers use their drill every single day—and not just for drilling. With the right bit, it becomes a countersinker, a nut driver, a wire brush, a hole saw, or even a basic mixer for glue or finish. Want to drill pocket holes or cabinet hardware? That’s your drill’s domain.

Look for a drill with variable speed and a good clutch system to avoid stripping screws. And if you’re doing more demanding work like Forstner bits, spade bits, or hole saws, a higher-torque cordless model or corded drill will give you better results.

Besides curating a selection of the best power drills on the market, ToolsToday offers the most important thing: top-tier drilling and boring bits from brands like Amana Tool. That includes brad point bits, CNC-compatible drills, countersinks, and hinge boring tools used by pros in cabinetry and furniture making.

Pro Tip: Keep a magnetic bit holder and an assortment of driver tips in your pocket or apron. Switching between drill and driver mode quickly makes your workflow 10× smoother.

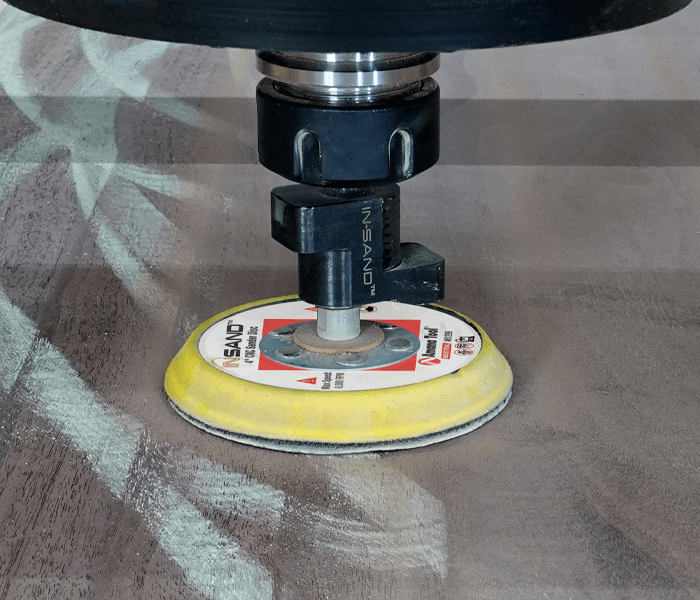

6. Random Orbital Sander

Sanding is where good projects become great. A random orbital sander (ROS) gives you fast, swirl-free results without the hand fatigue of sanding blocks or the directional sensitivity of a sheet sander.

Unlike traditional orbital sanders, a ROS moves both in a circular and elliptical pattern. That dual motion removes material efficiently without leaving noticeable scratch patterns—even when you ignore the grain direction.

If you want cordless freedom and precision, the Festool ETSC 125 is a standout choice. It delivers corded power with battery convenience, along with exceptional vibration control for extended use.

For CNC users or high-production environments, ToolsToday also carries the Amana Tool In-SAND CNC Sander. It fits in a router spindle or CNC machine and delivers consistent finish sanding across flat surfaces, edges, or contours—perfect for sign makers and custom shops.

Pro Tip: Start with 80- or 100-grit to remove tool marks, then move up to 150 or 180 for pre-finish sanding. Always vacuum between grits to prevent scratches from leftover debris.

7. Compound Miter Saw: Fast, Accurate Angles

When it comes to cutting clean, repeatable angles, nothing beats a compound miter saw. It’s your go-to tool for framing, molding, picture frames, trim, or any part that needs precision angles in multiple planes.

“Compound” refers to the saw’s ability to tilt the blade and rotate the base—letting you cut both bevels and miters in a single pass. This is essential for jobs like crown molding or furniture legs that require compound joints.

Although it's technically portable, most woodworkers mount their miter saw with outfeed supports or tables. Why? Because supporting long boards reduces tear-out, improves cut accuracy, and keeps your hands safer during crosscuts.

ToolsToday carries two standout options:

- JET Compound Miter Saws – Well-built, affordable, and great for most home and pro shops.

- Festool KSC 60 – Cordless, ultra-precise, and engineered for jobsite or high-end cabinet work. Worth the investment if every cut counts.

Pro Tip: For best results, always use a sharp fine-tooth blade for trim or finish work—and back up your cuts with a scrap block to minimize splintering.

8. Gent’s Saw: Precision Hand Saw for Joinery Work

When it comes to fine joinery—dovetails, tenons, small shoulders—few tools are as elegant or as precise as a gent’s saw. Designed for detail work, the gent’s saw features a rigid spine for controlled cuts and a straight, comfortable handle that encourages a pencil-grip hold for maximum accuracy.

The Blue Spruce 8" Gent’s Saw combines traditional design with modern craftsmanship. Its high-carbon steel blade and ultra-fine 20 TPI (teeth per inch) grind deliver clean kerfs and smooth tracking, even in hardwoods. The solid brass back adds just the right amount of weight to keep cuts steady and true.

This saw is ideal for those who appreciate the rhythm and control of hand-cut joinery. It pairs beautifully with a quality bench chisel for dialing in perfect fits—no sanding required.

Pro Tip: Let the saw do the work. Apply light pressure and use the full length of the blade to keep your cuts straight and chatter-free.

The Blue Spruce Jigsaw Blade Handle turns any Jigsaw Blade into a Small Hand Saw

The Blue Spruce Jigsaw Blade Handle turns any Jigsaw Blade into a Small Hand Saw

9. Jigsaw: Versatile Curves & Cuts, With Some Limitations

The jigsaw is a go-to handheld power saw for cutting curves, circles, and small openings. Unlike the Japanese pull saw, which cuts on the pull stroke, most jigsaws cut on the upstroke, making them closer to a “push saw” in how they engage the material. This means the blade tends to lift the wood fibers, which can sometimes cause splintering on the top surface.

That said, jigsaws shine when it comes to versatility. Change the blade type and you can cut wood, plastic, metal—even ceramic tile. The ability to switch blades quickly means a jigsaw can tackle jobs that would be difficult or impossible with other saws.

However, the jigsaw isn’t always the best choice for straight cuts—especially long ones—since its narrow blade can flex and wander. For straight rip cuts, a circular or table saw is a better tool.

Pro Tip: Use fine-toothed blades for clean cuts, and clamp a straightedge guide if you need straighter lines. Keep blades sharp and choose the right tooth pattern for your material.

10. Circular Saw: Portable Power for Straight Cuts

The circular saw is the most widely used handheld power saw, prized for its portability and versatility. It excels at straight cuts—ripping, crosscutting, and making bevel cuts—whether on sheet goods or framing lumber.

Interestingly, the circular saw is often the second power tool people buy after a drill, making it a cornerstone for both beginners and pros alike.

There is a key difference between circular saw blades and table saw blades: circular saw blades are typically designed to cut on the side opposite the blade’s rotation direction (usually clockwise), with thinner kerfs and tooth designs optimized for handheld control and portable cutting. Table saw blades are generally heavier and more rigid, suited for high-speed, precise cuts on fixed machinery.

Choosing the right blade is crucial. For example, a fine-tooth blade (60–80 teeth) works well for plywood and laminates, while a lower tooth count (24–40 teeth) blade is better for faster, rough cuts in framing lumber.

Pro Tip: Always match your blade to the material and cut type. A sharp, purpose-built blade is safer and produces better results than a dull, generic one.