The Science of Saw Blades: Understanding Tooth Count, Kerf, and Hook Angle

Choosing the right saw blade is essential for achieving precise, clean cuts while optimizing tool performance. For serious woodworkers and small manufacturers, understanding key blade characteristics—such as tooth count, kerf, and hook angle—can make all the difference in efficiency and cut quality. Whether you're cutting wood, melamine, aluminum, metal, plastic, or other materials, selecting the proper Amana Tool carbide-tipped saw blade ensures superior results.

Tooth Count: More Teeth vs. Fewer Teeth

Tooth count plays a crucial role in determining the type of cut a blade produces. Blades with fewer teeth remove material quickly, making them ideal for rip cuts along the grain. These blades reduce friction and heat buildup, minimizing the risk of burning the wood.

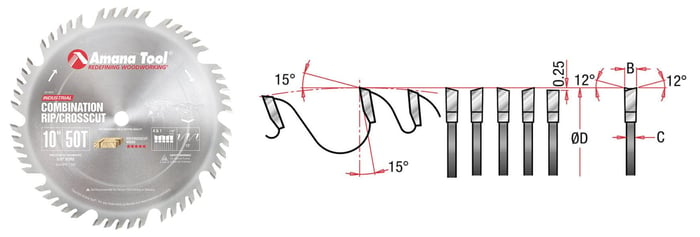

Amana Tool 610504 Carbide Tipped Combination Ripping and Crosscut 10 Inch D x 50T 4+1, 15 Deg, 5/8 Bore, Circular Saw Blade

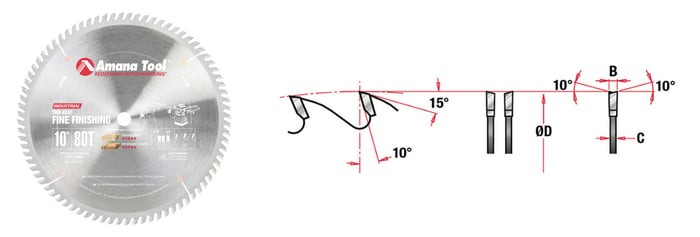

Amana Tool 610504 Carbide Tipped Combination Ripping and Crosscut 10 Inch D x 50T 4+1, 15 Deg, 5/8 Bore, Circular Saw BladeConversely, blades with a higher tooth count create finer cuts, which are essential for crosscutting and finishing work. For example, a 60-tooth or 80-tooth blade excels at cutting plywood and melamine with minimal chipping.

Amana Tool 610800-TS Carbide Tipped Thin Kerf Miter 10 Inch D x 80T ATB, 10 Deg, 5/8 Bore, Circular Saw Blade

Amana Tool 610800-TS Carbide Tipped Thin Kerf Miter 10 Inch D x 80T ATB, 10 Deg, 5/8 Bore, Circular Saw Blade

Dado sets, which feature stacked blades, allow for adjustable-width cuts used in joinery.

Kerf: Full vs. Thin Kerf Blades

Kerf refers to the width of the cut made by a saw blade. Full-kerf blades, typically 1/8" wide, offer stability and durability, making them a great choice for high-powered table saws and heavy-duty applications.

For the ultimate in general purpose saw blades, use the Prestige™ PR1040. It's massive tool-steel plate (.102" thick), expansion slots and copper plugs practically eliminate vibration.

For the ultimate in general purpose saw blades, use the Prestige™ PR1040. It's massive tool-steel plate (.102" thick), expansion slots and copper plugs practically eliminate vibration. Thin-kerf blades, usually around 3/32" wide, require less power to cut through materials, making them ideal for portable saws or applications where minimizing material waste is important. These blades also reduce strain on the motor, extending the life of both the tool and the blade.

Get super-fine cuts with our lines of fine-kerf contractor blades for stationary or portable machines.

Get super-fine cuts with our lines of fine-kerf contractor blades for stationary or portable machines.

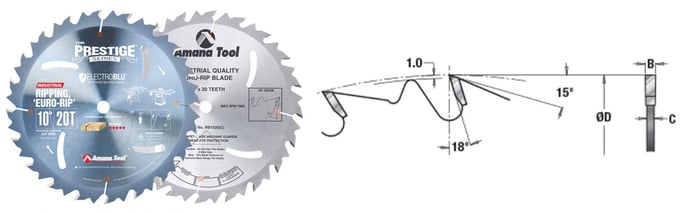

Hook Angle: Aggressive vs. Neutral

The hook angle, or rake angle, determines how aggressively the blade feeds into the material. A high positive hook angle (e.g., 18°) provides faster cuts, which is beneficial for ripping applications. However, aggressive angles can be harder to control and increase the likelihood of tear-out on delicate materials.

Euro-Rip Ripping Saw Blades With Cooling Slots and Anti-Kickback Feature; 10" to 16" Blades

A neutral or negative hook angle (0° to -5°) produces more controlled cuts, making these blades ideal for miter saws, radial arm saws, and cutting materials like melamine, laminate, or plasic, and non-ferrous metals. Negative hook angles help reduce chipping and improve safety by preventing the blade from pulling the material toward the operator.

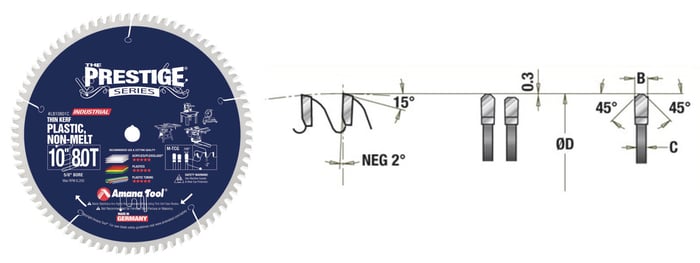

Amana Tool LB10801C Carbide Tipped Prestige Non-Melt Plastic 10 Inch D x 80T M-TCG, -2 Deg, 5/8 Bore Circular Saw Blade

Amana Tool LB10801C Carbide Tipped Prestige Non-Melt Plastic 10 Inch D x 80T M-TCG, -2 Deg, 5/8 Bore Circular Saw Blade

Choosing the Right Blade for Your Application

Matching the blade to the material and cutting operation is key to achieving professional results. For example:

- Rip Cuts in Hardwood: A 24-tooth full-kerf blade with a high hook angle is ideal.

- Fine Crosscuts in Plywood: A 60-tooth or 80-tooth thin-kerf blade with a negative hook angle minimizes splintering.

- Melamine and Laminates: A high-tooth-count blade with an alternate top bevel (ATB) or triple-chip grind (TCG) provides clean, chip-free edges.

- Aluminum and Non-Ferrous Metals: A specialized TCG blade with a negative hook angle ensures smooth cuts without grabbing.

Why Choose Amana Tool Saw Blades?

At ToolsToday, we offer a wide selection of Amana Tool carbide-tipped saw blades designed for superior performance across various materials. Whether you're working with wood, metal, plastics, or composites, Amana Tool blades deliver precise, long-lasting results.

By understanding the relationship between tooth count, kerf, and hook angle, you can confidently select the right saw blade for your next project, improving efficiency and cut quality while prolonging the life of your tools.