Making Shelf Pin Holes Using a Drill or a CNC Router

Drilling shelf pin holes is a common task in woodworking, particularly in cabinetry, where adjustable shelves are needed. The process can be done using either a handheld drill with a jig or a CNC router, and there are specific systems like the "Shelf 32" system that standardize the spacing and positioning of these holes.

The "Shelf 32" System (a.k.a. 32mm System)

Overview

The "Shelf 32" system, also known as the 32mm system, is a standard used primarily in European cabinet-making. This system is based on a 32mm spacing between holes, which aligns with the standardized sizing of European hardware such as hinges and drawer slides.

Hole Spacing

The holes are typically drilled 32mm apart in a vertical row. The first hole is generally set at 37mm from the edge of the cabinet or panel. This ensures that the hardware can be easily installed and aligned.

Applications

The 32mm system is widely used for adjustable shelving, cabinet construction, and installing hinges. It simplifies the manufacturing process, especially in mass production, as all components follow the same spacing standard.

Benefits of the 32mm System

The 32mm system increases efficiency in several ways, particularly in the context of mass production and standardized cabinetry. Here’s how:

1. Standardization of Components

- Interchangeable Parts: The 32mm system ensures that all components (such as hinges, drawer slides, and shelf pins) are standardized and can be easily interchanged between different cabinets and projects. This reduces the need for custom hardware or fittings, simplifying inventory management and procurement.

2. Simplified Manufacturing Process

- Consistent Measurements: Since the spacing between holes is standardized at 32mm, there is no need to measure or mark out hole positions manually for each piece. This consistency reduces the chance of errors and speeds up the manufacturing process.

- Pre-programmed CNC Machines: In a production environment, CNC routers can be pre-programmed with the 32mm system layout, allowing for rapid and repeatable drilling of shelf pin holes without the need for reprogramming or adjustments between jobs. This reduces setup time and increases throughput.

3. Reduced Setup Time

- Jigs and Tools Designed for 32mm: Many jigs, templates, and specialized tools are designed specifically for the 32mm system. This means that workers can quickly set up and align these tools without having to adjust for different measurements, leading to faster setup and more efficient production.

4. Faster Assembly

- Ease of Assembly: Because components like hinges and drawer slides are designed to work with the 32mm system, they align perfectly with the pre-drilled holes, making assembly quicker and more straightforward. There’s no need for adjustments or fine-tuning during assembly, which can save significant time, especially in large-scale production.

5. Flexibility in Design

- Modular Construction: The 32mm system supports modular construction, where different components and panels can be mixed and matched to create a variety of designs. This flexibility allows for greater customization without sacrificing efficiency, as the underlying system remains the same.

6. Improved Quality Control

- Consistency Across Products: With a standardized system, it's easier to maintain consistent quality across all products. The uniform spacing and positioning of holes ensure that every piece meets the same specifications, reducing the risk of defects and the need for rework.

7. Scalability

- Easier to Scale Production: The 32mm system is particularly advantageous when scaling production, as the standardization allows for the easy expansion of manufacturing processes without the need for significant changes to equipment or procedures.

Woodpeckers Shelf Pin and Drawer Slide Template delivers perfect spacing with your choice of two different drilling methods, self-centering drill bits or a router with a 3/8" template guide bushing.

Drilling Shelf Pin Holes with a Drill

Jigs

When using a drill, a shelf pin jig is often employed to ensure accurate and consistent spacing of the holes. These jigs typically have pre-set holes spaced at 32mm intervals and guide the drill bit straight into the workpiece.

Drill Bit

A brad point bit is commonly used because it creates clean, precise holes with minimal tear-out, which is important for both aesthetics and functionality.

Process

- Set up the Jig: Secure the jig to the workpiece. Some jigs have built-in clamps, while others require separate clamps.

- Drill the Holes: Insert the drill bit into each guide hole of the jig and drill to the desired depth. Depth stops can be used to ensure uniform depth across all holes.

- Repeat: Move the jig as necessary to complete all the holes along the length of the workpiece.

Festool 5mm Centrotec self-centering drill bit's centering mechanism rotates freely, eliminating burning or marring of your finished surface, and features a brad-point tip for ease of use and control.

Drilling Shelf Pin Holes with a CNC Router

Advantages

Using a CNC router for drilling shelf pin holes offers superior precision and consistency, especially in production environments where many pieces are being processed. The CNC machine can be programmed to drill the holes at exact intervals and depths, eliminating the need for manual measurement and setup.

Programming

The 32mm spacing can be programmed into the CNC machine, ensuring that all holes are drilled accurately. The machine can handle various panel sizes and configurations, making it versatile for different cabinetry designs.

Speed and Efficiency

A CNC router can drill multiple holes quickly and accurately, making it ideal for large-scale production. It also reduces the likelihood of human error.

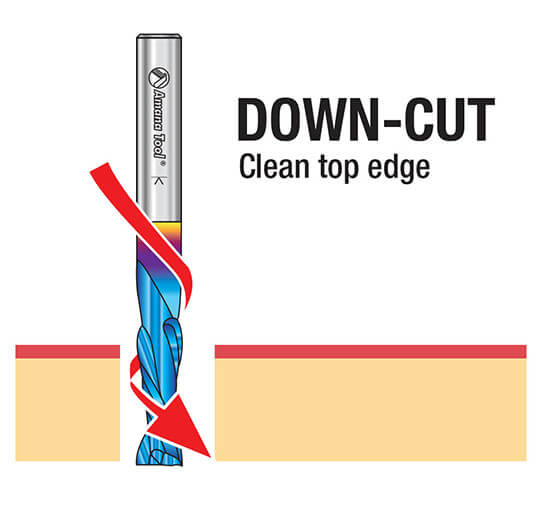

Many Spektra solid carbide spiral plunge bits are specifically designed to plunge shelf holes using a CNC machine.

Spektra CNC Bits Designed for Shelf Pin Holes

| Item # | Diameter | Cutting Height | Shank | Overall Length | # of Flutes | Rotation |

| 46211-K | 4mm | 3/4" | 1/4" | 2-1/2" | 2 | Downcut |

| 46202-K | 1/4" | 3/4" | 1/4" | 2-1/2" | 2 | Downcut |

| 46211-L-K | 5mm | 1" | 1/4" | 2-1/2" | 2 | Downcut |

| 46214-K | 3/8" | 1-1/4" | 3/8" | 3" | 3 | Downcut |

| 48219-K | 8mm | 1" | 8mm | 1-1/2" | 2 | Downcut |

| 48224-K | 10mm | 1" | 10mm | 3" | 2 | Downcut |

| 46210-K | 1/2" | 7/8" | 1/2" | 3" | 2 | Upcut |

| 46216-K | 1/2" | 1-1/2" | 1/2" | 3-1/2" | 3 | Downcut |

Considerations

Material

The type of material being drilled can affect the choice of drill bit and technique. For instance, harder materials may require a slower drill speed to avoid burning or dulling the bit.

Depth Control

Consistent depth is crucial for shelf pins to sit evenly. Depth stops on a drill or precision programming on a CNC router ensure that all holes are the same depth.

Dust Collection

Drilling multiple holes generates a lot of dust. Using dust collection systems with either a drill or CNC router can keep the workspace clean and improve visibility.

Conclusion

Drilling shelf pin holes, especially using the 32mm system, is a straightforward process that can be done manually with a drill and jig or more efficiently with a CNC router. The choice between these methods depends on the scale of the project, the desired precision, and the available tools. The "Shelf 32" system standardizes the process, ensuring compatibility with a wide range of hardware and making it easier to achieve professional results.