PRODUCT DETAILS

Click an item to expand and learn more

-

-

-

-

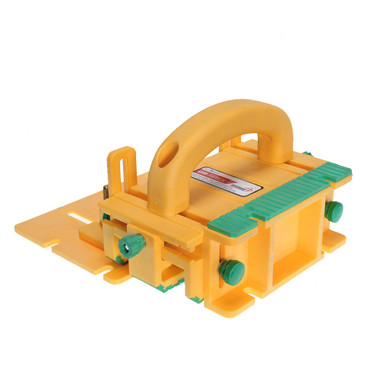

Why plastic?

The GRR-RIPPER is made of specially formulated high-impact plastics for good reason. It maintains its shape and rigidity, but also absorbs force if it makes contact with the blade. In other words, it won’t shatter or break your wrist.

I cut into my GRR-RIPPER, now what?

Every part of the GRR-RIPPER is individually replaceable, and compatible with all GRR-RIPPER models. Browse and swap out any damaged part with a replacement.

Will the GRR-RIPPER trip the sensor on my SawStop?

No. The plastic material will not trigger the safety mechanism on SawStop saws.

I have a GRR-RIPPER with black parts - will yellow replacement parts fit?

Yes - the design is exactly the same. Black and yellow GRR-RIPPER parts are interchangeable.

My GRR-RIPPER doesn’t seem as grippy as it used to - what gives?

Over time, dust and other contaminants can build up and compromise the effectiveness of the Green GRR-RIP material. Cleaning the gripping surface with denatured alcohol should restore your GRR-RIPPER to its original glorious grippy-ness. In rare cases, prolonged exposure to sunlight can damage the gripping material, so keep it out of direct sunlight.

Will the GRR-RIPPER work on my table saw?

It will work on any standard table saw with a fence and a blade.

Can I use the GRR-RIPPER with the blade guard on my table saw?

The GRR-RIPPER passes over the blade so there can’t be anything in the way. Don’t worry, the GRR-RIPPER is your moving blade guard.

Why would I need two GRR-RIPPERs?

We recommend using two GRR-RIPPERs when cutting stock longer than your table saw top. In order for the GRR-RIPPER to work properly, it needs to be on top of the material, with the material on the table stop. If you stop feeding material to reposition your GRR-RIPPER, the saw blade will leave blade marks and burning. With two GRR-RIPPERs, you can feed stock continuously using the hand-over-hand method, resulting in better cut quality.

Is the GRR-RIPPER OSHA compliant?

Yes. OSHA regulations state that “...in a workplace, regulations require that unsafe saws be removed from service immediately, push sticks or push blocks be provided at the work place for guiding or pushing material past the blade, and emphasis be placed on the cleanliness around woodworking machinery and, in particular, the effective functioning of guards and prevention of fire hazards. 29 CFR1910.213(s)