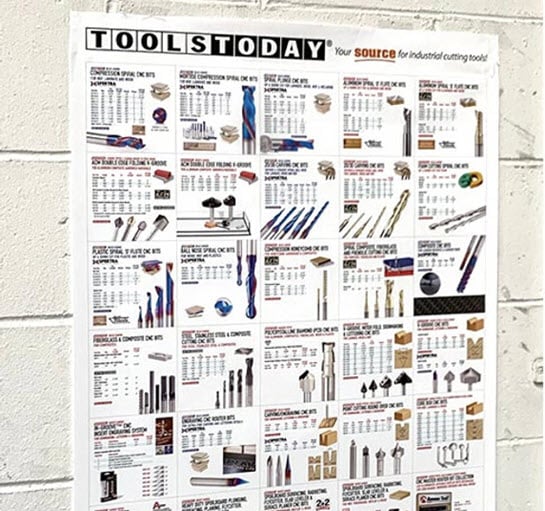

CNC Tooling Guide Poster

This poster will look great in your shop, garage, office and walls. Our Toolstoday website has the most complete list of all the tooling we offer, but it can be overwhelming. It’s nice to quickly reference the best router bits for wood, aluminum, plastics, or other advanced materials using this 24″x 36″ poster. Pick up your CNC tooling guide poster to hang near your machine for easy reference.

![]()

Choosing the right bit for the material you’re using can often be confusing, but Toolstoday’s Matt Plumlee is going to highlight a few categories from the poster to show you how it can make bit selection much easier for you!

Compression Bits

When making through cuts on MDF, laminate and wood there are few router bits that perform better than a compression bit.

Compression bits have a unique grind on them with an upcut portion at the bottom of the bit and a downcut portion at the top of the bit.

This creates a clean cut on the top and bottom surface of the material.

These bits are also designed to cut material in a single pass, provided your machine can handle it, so using them will save machining time by not having to make multiple passes.

Upcut / DownCut Bits

Upcut and Downcut bits are perfect choices when only one clean face is required or for pocketing operations in wood, laminate, MDF and melamine.

A downcut bit will leave a perfectly clean top surface of the material, making it great for pocketing or for profile cuts where the you will be rounding over the bottom edge.

Upcut bits will leave a perfectly clean bottom edge but may chip out the top edge. This is perfect for deep profile cuts as the upcut will evacuate chips better or for a large area clearance tool for v-carves.

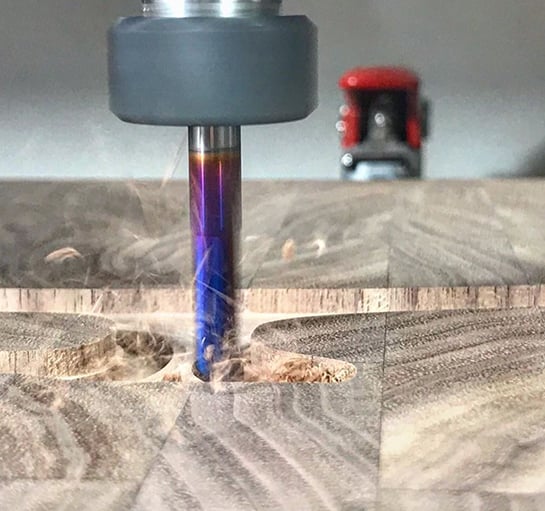

Non-Ferrous Metals: Aluminum, Brass, & Copper

ZrN coated or uncoated spiral ‘O’ flute bits should be your go-to bits when cutting soft non-ferrous metals like aluminum, brass, copper etc.

The single flute design and mirror finish on these bits help the metal chips jump right off of the bit.

The ZrN coating will help prolong tool life by keeping the bit cooler and preventing build up on the bit.

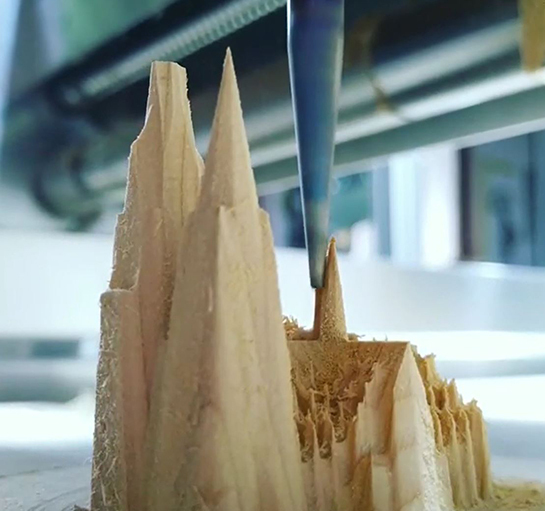

2D/3D Wood Carving Bits

These Spektra coated 2D/3D Carving bits are perfect for cutting 2D or 3D designs in wood, laminate and MDF.

Using the right bit makes all the difference in the quality of the carve. These bits are certainly up for the task and will give you perfectly clean cuts.

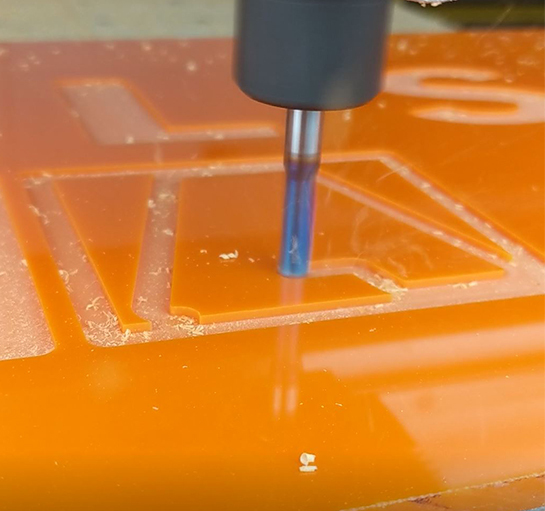

Plastic Cutting Bits

Cutting plastic has never been easier than it is with the Spektra coated Spiral ‘O’ flute bits. These bits absolutely fly through plastics, creating perfectly clean cuts.

The Spektra coating and mirror finish on these bits help the plastic jump off the bit and prevents any melting of the plastic.

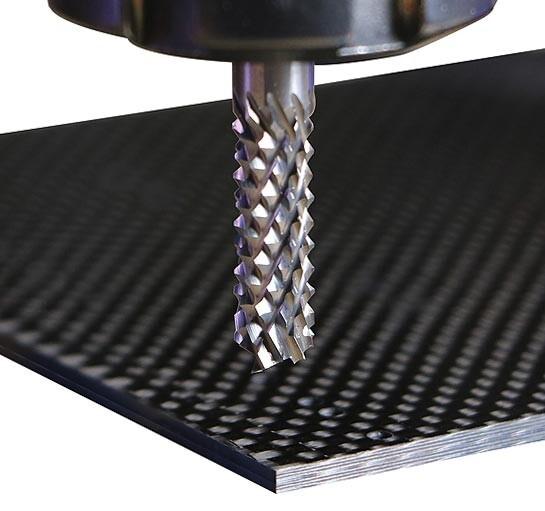

Router Bits for Composites

Composite materials can be difficult to cut, but our Honeycomb Composite Cutting bits will make it easy for you! We offer bits for cutting carbon fiber, fiber glass, phenolic and many more.

We’re sure to have the bit to fit the composite material you’re cutting.

Carbide Insert Signmaking Bits

Making detailed v carves in wood, laminate and MDF is made much easier with the insert carbide v-groove bits.

These bits feature a replaceable carbide insert that stays sharper for longer than braised v-bits while also decreasing cost over time.

You keep the tool body for life, only replacing the inexpensive insert when it becomes dull, saving you money in the long run. You’ll love the buttery smooth cuts these v-groove bits make.

Extra Fine Engraving Bits

For the smallest of details in wood, plastic, laminate and MDF you can’t go wrong with the extra fine engraving bits. These bits will leave nice clean cuts even on tiny details.

We offer sizes ranging from 15°-45° to best suit your needs.

These bits also feature a small flat tip widths to leave perfectly smooth bottoms of the engraving.

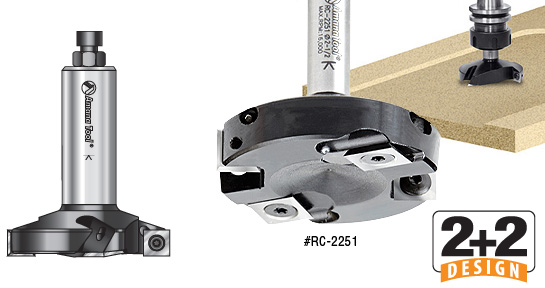

Spoilboard / Flattening Bits

Whether you’re surfacing a spoilboard or flattening slabs you’re sure to love the Heavy Duty Flattening bits.

These bits feature replaceable carbide inserts that can be rotated to get 4 lives out of the same insert.

After that, just replace the inexpensive inserts and do it all over!

With their wing design and small contact surface with the wood, these bits leave very clean cuts, minimizing any chance of burning. This is sure to become your go-to flattening bit.

In conclusion, we hope this guide has helped you select which bits to use for the different materials you will commonly encounter while using a CNC. We hope that you will try out a new material type using one of these recommended types of router bits!