Best CNC Workholding Methods for Woodworking

There are no shortage of CNC workholding methods, but Toolstoday’s Matt Plumlee is going to go through each category of workholding methods for wood and break down what each one is used for and discuss what has worked best for him.

Top Hold Down Clamp

Top hold down clamps are probably the most common method of holding down material on a CNC machine but, in my opinion, are not the best option except for in certain scenarios. The problem with top hold down clamps is, generally, there is a lot of the clamp sticking above the work piece which make for perfect obstacles to accidentally run your bit right into. Worse yet, many top hold down clamps are made from aluminum which can easily break or ruin a bit when running into it unexpectedly at full speed. You do your best to make sure that you’re setting the clamps up in areas where you won’t hit them with your design, but every one of my aluminum clamps I have has a nice scar in it where I’ve accidentally run a bit into it.

That being said, top hold down clamps are extremely useful for working with plywood that may have a slight cup in it. You can use these clamps, strategically placed, to clamp the material flat to your wasteboard allowing you to machine it without worrying about it not being flat. The best top hold down clamps I have used are the Essential clamps that come in the Carbide 3D Get a Grip Workholding Kit, there are also various other useful CNC workholding tools in this kit as well. These clamps are very strong and grip with a small lip touching the material with very little sticking above the work piece making it difficult for your bit to find the clamps and hit them. If you’re going to use top hold down clamps, I would highly recommend these. If you want to use more traditional top hold down clamps, be careful where you set them up and ensure they are placed where the bit is not going come into contact with them.

Side Holding

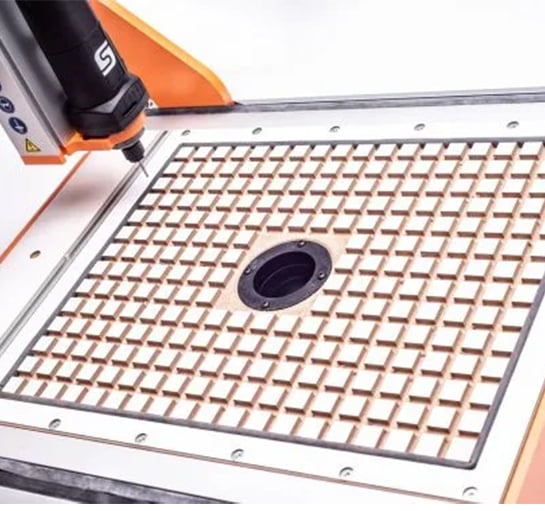

This is easily my favorite CNC workholding method. In fact I made an entire workholding wasteboard around this method. Please note, these plans are designed for the Stepcraft M.1000 CNC machine, if you are using these plans on a different CNC machine you will need to adjust the file by adding, or subtracting, rows/columns of holes to get it to fit the size you need and adjust how its held down to the stock wasteboard as each CNC machine is going to be a bit different. That being said, the plans for the workholding wasteboard do also come with the design for the cam clamps that are the star of the show here.

This system has a fence that is machined perfectly square to the CNC machine and the cam clamps bolt into the wasteboard and rotate to provide a large amount of side pressure on the material pushing up against the fence. This holds workpieces securely in place while cutting without having any clamps to run into on top of the material. This is an ideal workholding solution when cutting many of the same parts as well. Once a part is done cutting, simply turn the clamps to release the workpiece, vacuum off any saw dust left, place a new piece down, rotate the clamps to put pressure again and within just a few seconds you have another piece securely held in place and ready to cut again.

Another great option for side holding clamps, utilizing the same workholding wasteboard, would be the Carbide 3D Tiger Claw Clamps. These low profile stainless steel clamps are able to apply a ton of side pressure to a work piece to ensure it is securely held in place.

Where side hold down clamps are not ideal is when dealing with stock that is not flat. If you are going to be v-carving a design into a board that isn’t flat using side hold down clamps will not remove that bow or cup in the board leaving you with an uneven v-carved design. Some of the other workholding methods mentioned here would be better for that situation.

Tape

Using double sided tape is going to be the first option I’m covering which doesn’t require any sort of t-track or bolt pattern to use making it a great option for someone just starting out with a CNC machine. I personally have tried many different types of double sided tape and have found the XFasten Double Sided Woodworking tape to be the best that I have tried. It sticks great to the material and wasteboard, but is also easy to remove later leaving little to no residue when removing. Double sided tape works great for holding thin stock to the machine as well and is often a go to for me when working with thin stock, even given all of the other workholding methods available.

Another tape option is to use painters tape and CA glue. Simply put painters tape on the back of your work piece and place painters tape down on your wasteboard where you want to place your material. Apply CA glue to the back side of your work piece and spray accelerator on the tape on the wasteboard. Place the work piece down onto the tape on your machine and hold it in place firmly for 30 seconds. Your piece is now held securely in place with tape covering all areas. In most cases this would allow you to cut a piece with many smaller parts where adding tabs to hold the offcuts wouldn’t be an option. I also regularly use this method when cutting non-ferrous metals on the CNC machine as it is an incredibly strong hold down method. It does take a bit of time to setup and uses a lot of tape, so it’s not a great option to use for every project, but is the best option for certain situations when cutting many small parts.

Screws

Screws are likely one of the first hold down methods people use when getting a CNC machine as it’s something they likely already have. This is a good workholding option for awhile, but in time will create lots of holes and create an uneven wasteboard surface. If you are using this method, be sure to use a supplementary wasteboard, by placing another piece of wood, typically MDF, on top of the stock wasteboard held in place using screws or double sided tape. This will prevent you putting lots of holes into the stock wasteboard, which is typically much more difficult to replace. You want to keep that stock wasteboard as clean as possible so you always have a nice reference surface to work off of. When using screws, you need to be mindful of where they are placed to ensure they are outside of your toolpath.

Brad Nails are similar to using screws to hold pieces down, but they are a bit quicker to install and don’t leave as big of holes, but all of the same principals mentioned above with screws, apply here. However, there is a composite nailer that shoots hard plastic nails instead of metal nails. The Omer B17P Composite Nailer is a great addition for holding down material without having to worry as much about placement. If a bit contacts a composite nail, it will simply cut right through it with no damage at all to the bit or the material.

Vacuum Table

The vacuum table is one of the more specialized options listed here and is not something that all CNC machines are able to accommodate. If you do a quick search on YouTube you will see plenty of people that have made their own DIY vacuum table, and this may certainly be an option for you. I use the vacuum table on the Stepcraft M.1000 and Stepcraft Q.408 CNC machines regularly and it is an awesome hold down method to have, but is not suited for everything in my opinion. Where vacuum tables struggle is holding down material that is not perfectly flat. If you are wanting to surface a slab, the vacuum table will not be powerful enough to pull a piece of hardwood flat to hold in place securely. The same is true for smaller pieces of material. Once you get down to a certain size, there just simply isn’t enough area for it to be held in place securely.

Where a vacuum table absolutely beats all other methods of workholding is when it comes to working with larger pieces of sheet good material and cutting parts from those. It is able to pull small twists and bows out of sheet goods to suck them down perfectly flat and you can cut parts from it without the need for tabs, unless you are cutting out some really small pieces, as it will hold things in place for you. The production speed it provides is unmatched as you can simply place a piece of material down, turn on the vacuum and begin cutting. If you’re working with a lot of sheet goods, this is absolutely the best workholding method for you!

In conclusion, we hope that this guide has provided you with many different options and has helped you figure out what workholding method is going to work best for you and your projects. Each person is different and each project is different so I’m sure you will find yourself using more than one of these methods in upcoming projects!

You can get involved in the ToolsToday community in a number of ways and also make money and save money. You can follow us on the below social media networks and also take part in our Insider reward program and our Affiliate program.